Chapter 2

2-19

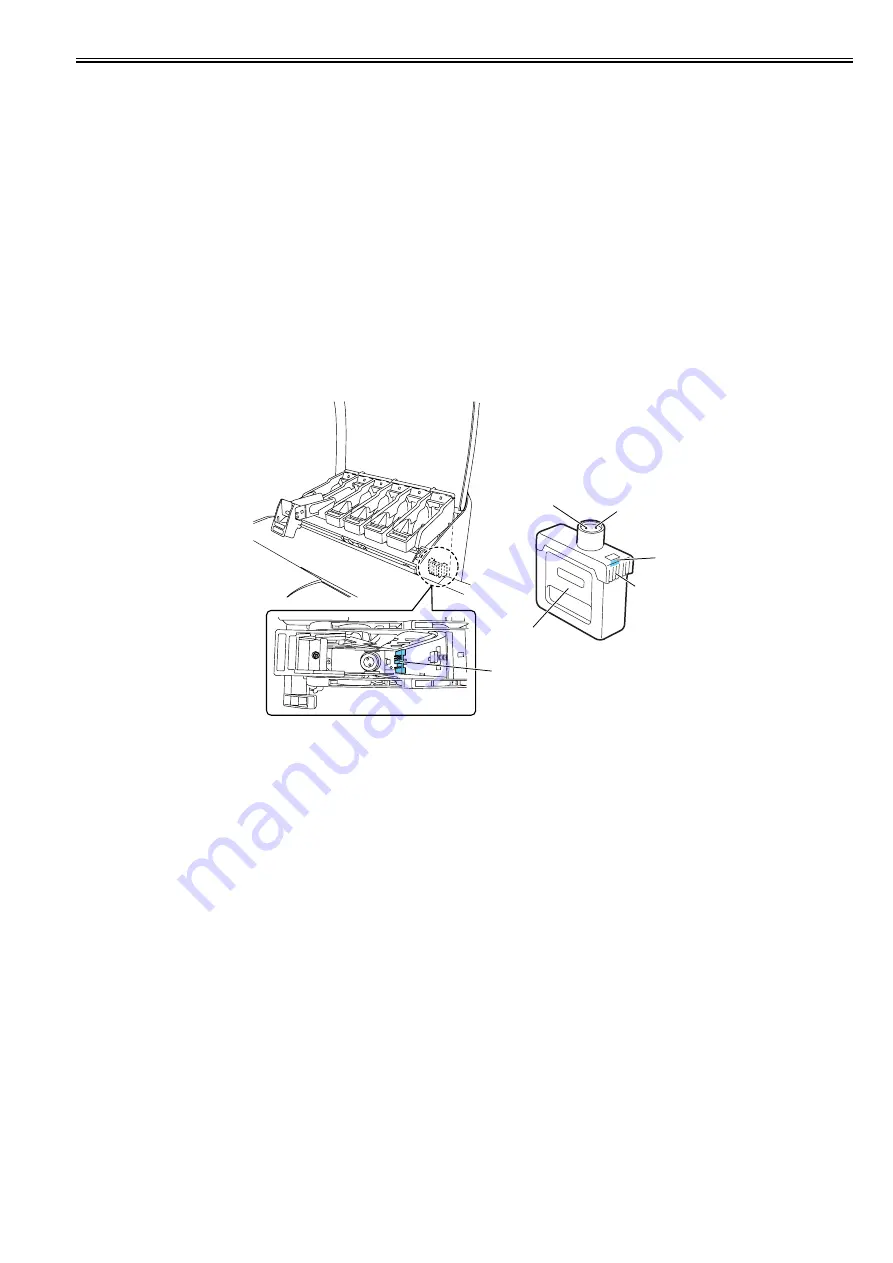

2.3.2.2 Ink Tank Unit

2.3.2.2.1 Structure of Ink Tank Unit

0020-5487

iPF810 / iPF820

a) Ink tanks

The ink level in each ink tank is memorized in EEPROM attached to the tank and is detected as a dot count on the basis of the EEPROM information.

When an electrode attached to a hollow needle detects no continuity, it displays a message reporting that the ink tank is nearly empty.

If the dot count reaches a predesigned value in this state, an ink out condition is assumed.

b) Ink port

Depressing the ink tank fixer lever on the printer would cause would cause a hollow needle to pierce the ink tank port sealed by a rubber plug, linking the ink passage

of the ink to the printer.

c) Air passage

Depressing the ink tank fixer lever on the printer would cause an open hollow needle to pierce the air passage sealed by a rubber plug releasing the internal pressure

of the ink tank to keep it constant.

d) Notches for preventing incorrect installation

Ink tanks are furnished with a notch for preventing incorrect installation.

If the installation of an ink tank in incorrect position is attempted, the notch would interfere with it, preventing its installation.

The ink tank fixer lever won't lower without the ink tank fully inserted to reach the mounting position, so the ink cannot be supplied.

F-2-10

T-2-3

[1]

Ink tank

[4]

Air passage

[2]

EEPROM

[5]

Notch for preventing incorrect installation

[3]

Ink port

[5]

[5]

[2]

[1]

[4]

[3]

Содержание iPF800 Series

Страница 1: ...Aug 13 2008 Service Manual iPF800 series ...

Страница 2: ......

Страница 6: ......

Страница 11: ...Chapter 1 PRODUCT DESCRIPTION ...

Страница 12: ......

Страница 14: ......

Страница 38: ...Chapter 1 1 24 Hold this lever to pull out the lower roll unit ...

Страница 90: ...Chapter 1 1 76 3 Push in the left and right Basket Rods toward the back all the way until they stop F 1 41 ...

Страница 100: ...Chapter 1 1 86 ...

Страница 101: ...Chapter 2 TECHNICAL REFERENCE ...

Страница 102: ......

Страница 147: ...Chapter 2 2 43 This function relays the image data from the main controller PCB to the printhead ...

Страница 158: ......

Страница 159: ...Chapter 3 INSTALLATION ...

Страница 160: ......

Страница 162: ......

Страница 176: ...Chapter 3 3 14 ...

Страница 177: ...Chapter 4 DISASSEMBLY REASSEMBLY ...

Страница 178: ......

Страница 180: ......

Страница 227: ...Chapter 4 4 47 Media type Gloss photo paper 2 Paper gap adjustment Service mode SERVICE MODE ADJUST GAP CALIB ...

Страница 238: ...Chapter 4 4 58 ...

Страница 239: ...Chapter 5 MAINTENANCE ...

Страница 240: ......

Страница 242: ......

Страница 246: ...Chapter 5 5 4 5 Close upper cover 1 F 5 6 1 ...

Страница 247: ...Chapter 5 5 5 ...

Страница 248: ......

Страница 249: ...Chapter 6 TROUBLESHOOTING ...

Страница 250: ......

Страница 252: ......

Страница 274: ......

Страница 275: ...Chapter 7 SERVICE MODE ...

Страница 276: ......

Страница 278: ......

Страница 301: ......

Страница 302: ......

Страница 303: ...Chapter 8 ERROR CODE ...

Страница 304: ......

Страница 306: ......

Страница 318: ...Chapter 8 8 12 ...

Страница 319: ...Aug 13 2008 ...

Страница 320: ......