2

2

2-22

2-22

Technology > Intermediate Process Tray Assembly > Stacking Operation

Technology > Intermediate Process Tray Assembly > Stacking Operation

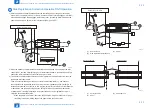

At the second stack operation or later (some paper is already loaded on the operation

tray), the swing guide is already lifted and the paddle and feed belt pushes the paper to the

operation stopper.

At this time, the height of the paddle, feed belt and upper guide is adjusted depending on

the stack amount of the paper on the operation tray.

[1]

[2]

[3]

[6]

[7]

[5]

[4]

[1] Paper

[5] Upper guide

[2] Stack delivery roller

[6] Paddle

[3] Swing guide

[7] Feed belt

[4] Operation stopper

NOTE:

Upper guide is to hold the paper and avoid the paper from bending when the paper is

pushed to the operation tray.

F-2-29

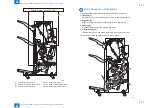

4) When the trailing edge of the paper reaches the operation stopper, the stack delivery

roller(*1) and the paddle(*2) stop rotating and the swing guide(*1) is lifted.

*1; At the first stack operation only

*2; At the second stack operation or later

[1]

[2]

[3]

[5]

[4]

[1] Paper

[4] Operation stopper

[2] Stack delivery roller

[5] Swing guide

[3] Sort delivery roller

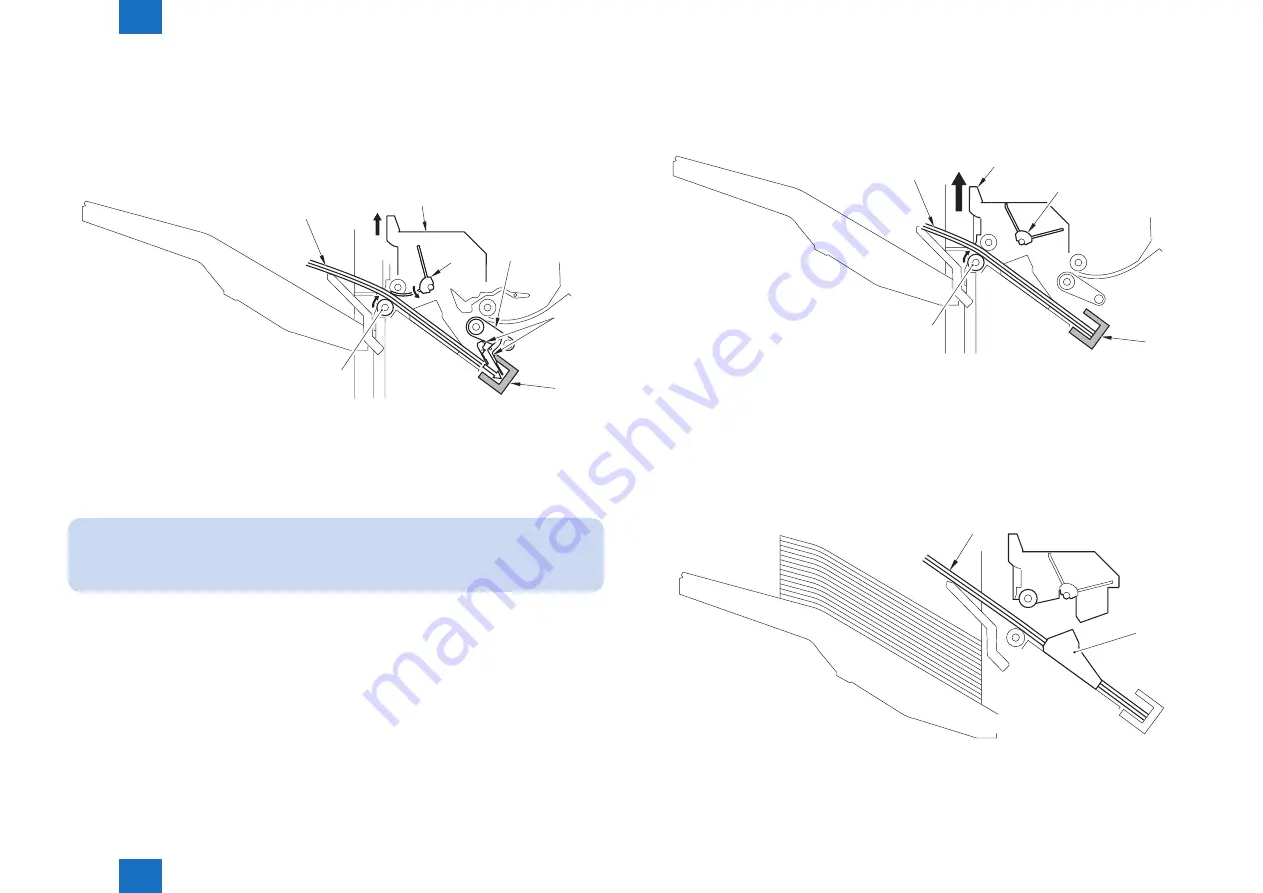

5) Front/rear alignment motor (M9/M10) drive and they move the alignment plate to the

front/rear to align the paper. This operation is executed every time the paper is fed to the

operation tray.

[1]

[2]

[1] Paper

[3] Alignment plate

[2] Operation tray

F-2-30

F-2-31

Содержание Booklet Finisher-D1

Страница 12: ... Notes Before Servicing Points to Note at Cleaning Safety Precautions ...

Страница 14: ...1 1 Product Outline Product Outline Product Specifications Names of Parts ...

Страница 60: ...3 3 Periodic Servicing Periodic Servicing User Maintenance Maintenance and Inspection ...

Страница 177: ...5 5 Adjustment Adjustment Basic Adjustment Adjustment at Time of Parts Replacement Auxiliary Adjustment ...

Страница 315: ...6 6 Troubleshooting Troubleshooting Upgrading ...

Страница 357: ... Service Tools Solvents and Oils List of Signals General Circuit Diagram Appendix ...