5

5

5-67

5-67

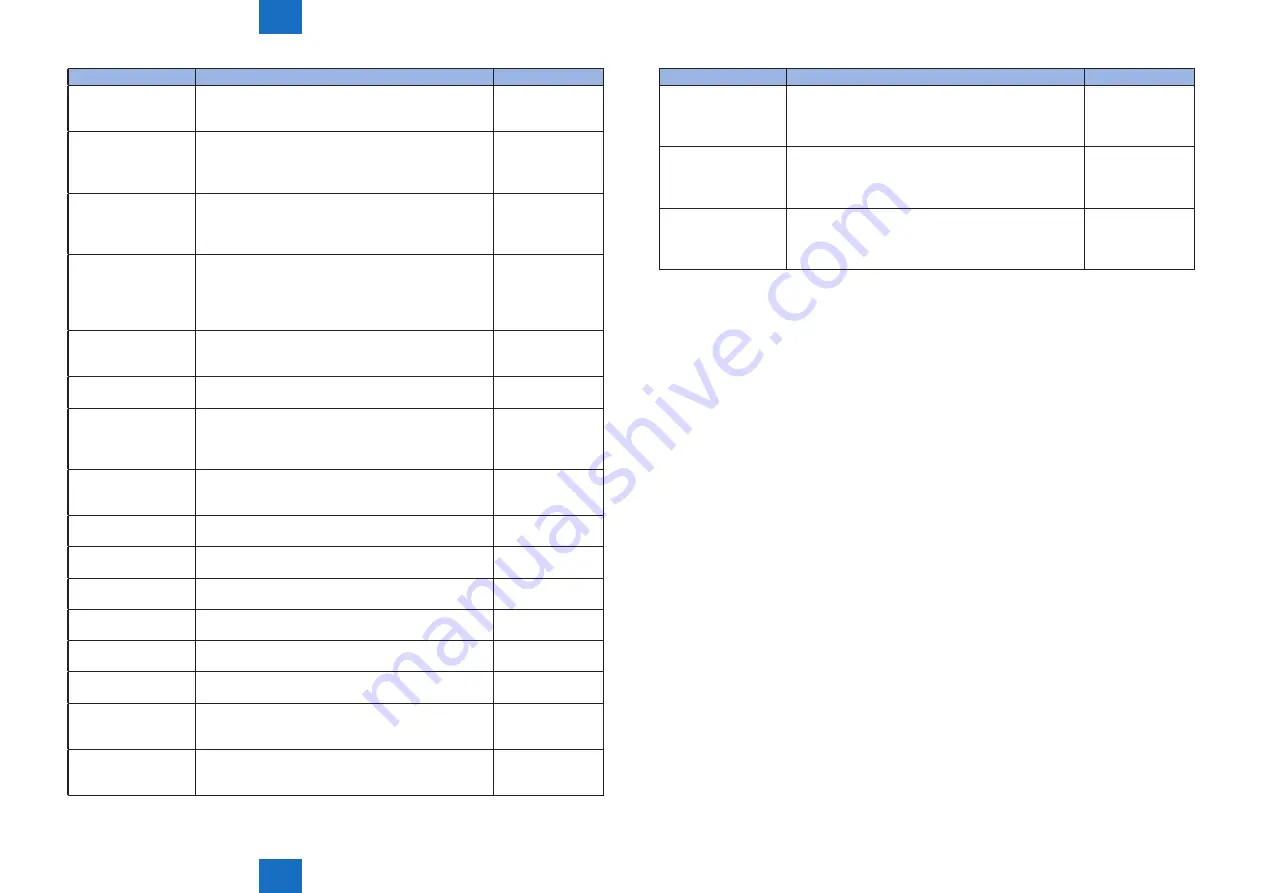

Adjustment > Auxiliary Adjustment > Outline

Adjustment > Auxiliary Adjustment > Outline

Adjustment Type

Symptom, adjustment timing

Reference

Adjusting Paddle

Height

• When stacking failure occurs on the tray with thin

paper

• When staple alignment failure occurs

Adjustment in the Case

of Failure in Stacking

Performance of Tray

(upper curl)

When stacking failure occurs on the tray (when upward

curl occurs)

Adjustment in the Case

of Failure in Stacking

Performance of Tray

(lower curl)

When stacking failure occurs on the tray (when

downward curl occurs)

Adjustment in the Case

of Failure in Stacking

Performance of Tray

(run-on of paper when

using thin paper)

When stacking failure occurs on the tray with thin paper

Adjustment in the Case

of Canceling Limit for

Tray Stack

When canceling stacking limit of the tray for coated

paper or extra-large paper

Adjusting Alignment for

Saddle Stapling

When staple positions (saddle delivery) are displaced

at the rear side and the front side

Adjusting Engagement/

Disengagement

Position of Saddle

Disengagement Roller

When staple position is displaced significantly

Adjusting Feeding

Distance of Saddle

Disengagement Roller

When staple position is displaced

Adjusting Side

Registration of Saddle

When jam occurs frequently at the Saddle Stack Guide

Setting of Pressless

Mode

When paper wrinkle occurs

Adjusting Delivery

Angle

When paper is curled

Setting of Tray Speed When abnormal noise is heard at the time of lifting/

lowering a tray after replacement of the Tray Motor

Changing Lower

Delivery Mode

When delivering non-stapled papers to the Lower Tray

Setting of Stop-less

Stacking

When paper wrinkle occurs

Adjusting Hole

Positions in Feeding

Direction

When adjusting the punch hole position from paper

edge

Upper/Lower Neat

Paddle position

adjustment

When paper displacement in feed direction occurs with

the Upper Tray or the Lower Tray

Adjustment Type

Symptom, adjustment timing

Reference

Punch skew tolerance

adjustment mode

When displacement of hole position (within 8.5 mm)

occurs and paper is skewed on the way from when it

passes through the Delivery Outlet until it is aligned

with the Alignment Plate at the time of delivery.

Process Tray alignment

operation adjustment

mode with A4R/LTRR

size paper

When prioritizing productivity of A4R and LTRR size

paper with the Lower Tray (without inner punching)

Side registration

position fine

adjustment mode (shift

amount change)

When paper corner is bent or caught with custom size

paper

T-5-9

Содержание Booklet Finisher-D1

Страница 12: ... Notes Before Servicing Points to Note at Cleaning Safety Precautions ...

Страница 14: ...1 1 Product Outline Product Outline Product Specifications Names of Parts ...

Страница 60: ...3 3 Periodic Servicing Periodic Servicing User Maintenance Maintenance and Inspection ...

Страница 177: ...5 5 Adjustment Adjustment Basic Adjustment Adjustment at Time of Parts Replacement Auxiliary Adjustment ...

Страница 315: ...6 6 Troubleshooting Troubleshooting Upgrading ...

Страница 357: ... Service Tools Solvents and Oils List of Signals General Circuit Diagram Appendix ...