5

5

5-11

5-11

Adjustment > Basic Adjustment > Adjusting Sensor Light Intensity > Procedure

Adjustment > Basic Adjustment > Adjusting Sensor Light Intensity > Procedure

■

Procedure

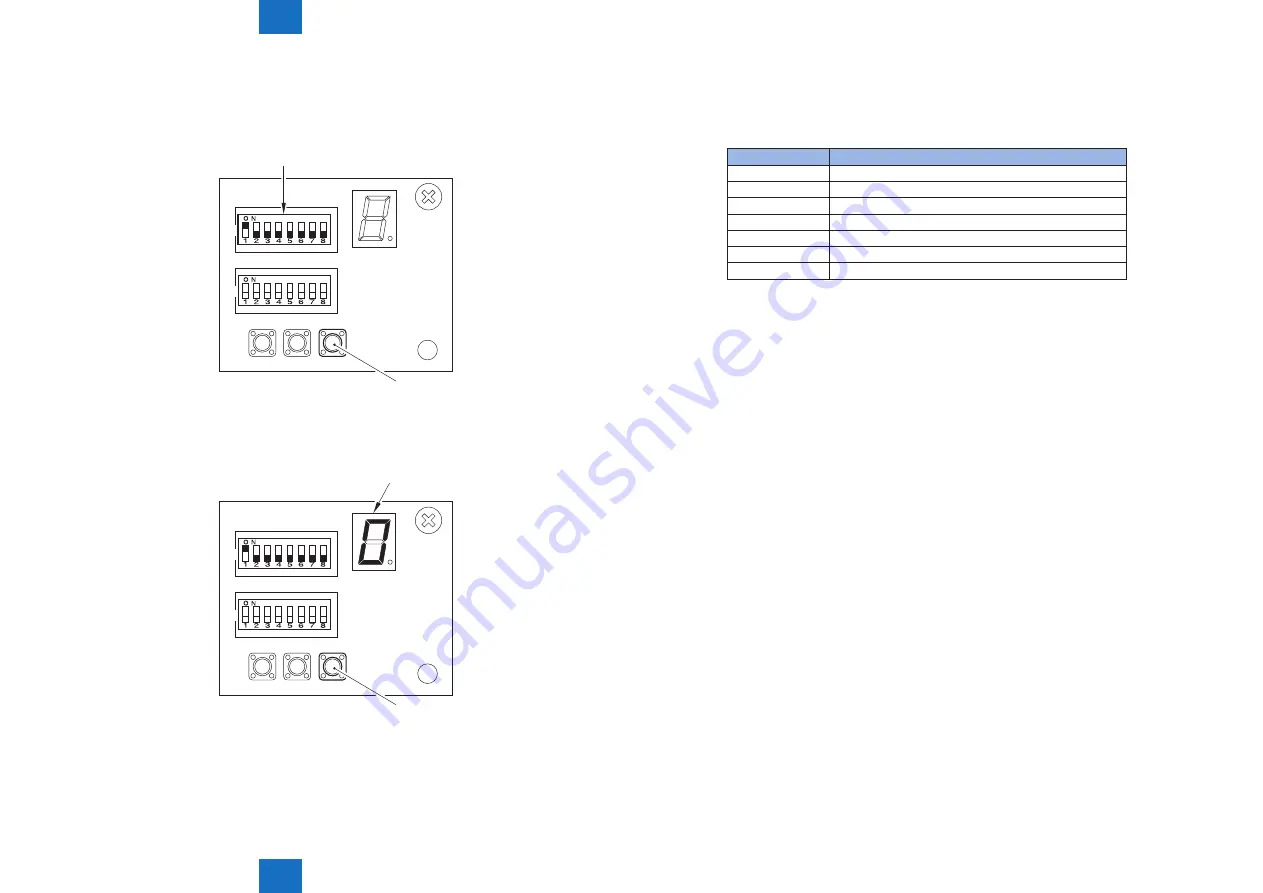

1) Set DIP switch SW382 [1] on the switch PCB as shown in the figure (1: ON), and then

press ENTER (SW385) button [2] to start adjustment for sensor light intensity.

SW382

SW381

SW383

(-)

(+)

ENTER

SW384 SW385

DSP381

[2]

[1]

2) Check that the LED [1] indicates with lighted "0". Press ENTER (SW385) button [2] to

complete adjustment for sensor light intensity.

SW382

SW381

SW383

(-)

(+)

ENTER

SW384 SW385

DSP381

[2]

[1]

F-5-24

F-5-25

3) If the sensor is faulty (The LED indicates with blinking "0"), press + (SW384) [1]/ - (SW383)

[2] button to find the code number on the blinking LED [3], and then replace the faulty

sensor correspondingly.

Code Number

Sensor Name

1

Buffer path 1 sensor PCB (UN13)

2

Buffer path 2 sensor PCB (UN14)

3

Lower path sensor PCB (UN22)

4

Side registration sensor PCB (UN12)

5

Punch waste full level sensor PCB (UN21)

6 to 8

Tray A paper surface sensor (UN16)

9, A, b

Tray B paper surface sensor (UN18)

T-5-3

Содержание Booklet Finisher-D1

Страница 12: ... Notes Before Servicing Points to Note at Cleaning Safety Precautions ...

Страница 14: ...1 1 Product Outline Product Outline Product Specifications Names of Parts ...

Страница 60: ...3 3 Periodic Servicing Periodic Servicing User Maintenance Maintenance and Inspection ...

Страница 177: ...5 5 Adjustment Adjustment Basic Adjustment Adjustment at Time of Parts Replacement Auxiliary Adjustment ...

Страница 315: ...6 6 Troubleshooting Troubleshooting Upgrading ...

Страница 357: ... Service Tools Solvents and Oils List of Signals General Circuit Diagram Appendix ...