2

2

2-5

2-5

Technology > Stacking Unit > Overview

Technology > Stacking Unit > Overview

Stacking Unit

Overview

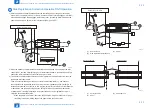

The stacking block moves up and down the 2 delivery trays according to the instructions from

the finisher controller PCB.

Finisher controller PCB

UN15

UN17

UN18

UN16

PS34

PS35

PS32

PS33

Tray A

Tray B

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[11]

[10]

M22

M23

SL9

F-2-5

[1] Tray B paper detection signal

[7] Tray A lift motor drive single

[2] Tray B paper surface detection light-

emitting signal

[8] Tray A lift motor rotation detection

signal

[3] Tray B paper surface detection light-

receiving signal

[10] Tray B lift motor drive signal

[11] Tray B lift motor rotation detection

signal

[4] Tray A paper detection signal

[5] Tray A paper surface detection light-

emitting signal

[6] Tray A paper surface detection light-

receiving signal

M22 : Tray A lift motor

UN15 : Tray A paper side sensor board

(emitter)

M23 : Tray B lift motor

UN16 : Train A paper side sensor board

(receiver)

PS32 : Tray A paper sensor

UN17 : Tray B paper side sensor board

(emitter)

PS33 : Tray A paper sensor

UN18 : Train B paper side sensor board

(receiver)

PS34 : Tray A lift motor rotation sensor

PS35 : Tray B lift motor rotation sensor

Содержание Booklet Finisher-D1

Страница 12: ... Notes Before Servicing Points to Note at Cleaning Safety Precautions ...

Страница 14: ...1 1 Product Outline Product Outline Product Specifications Names of Parts ...

Страница 60: ...3 3 Periodic Servicing Periodic Servicing User Maintenance Maintenance and Inspection ...

Страница 177: ...5 5 Adjustment Adjustment Basic Adjustment Adjustment at Time of Parts Replacement Auxiliary Adjustment ...

Страница 315: ...6 6 Troubleshooting Troubleshooting Upgrading ...

Страница 357: ... Service Tools Solvents and Oils List of Signals General Circuit Diagram Appendix ...