2

2

2-21

2-21

Technology > Intermediate Process Tray Assembly > Stacking Operation

Technology > Intermediate Process Tray Assembly > Stacking Operation

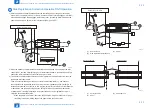

CAUTION: Stack Delivery Auxiliary Function

This machine is equipped with the stack delivery auxiliary mechanism as a means of

preventing misalignment of extra-length paper.

Misalignment occurs when the trail edge of paper hangs down on its own weight

at the stack delivery operation. The paper is then pulled back in the direction of the

arrow, causing its lead edge to move away from the stopper. The tray auxiliary plate is

pushed outside the machine before delivery occurs to hold the lead edge of paper. This

prevents misalignment. The tray auxiliary plate is pulled inside the machine at the end

of the delivery operation.

[5]

[1]

[2]

[3]

[1]

[2]

[3]

[4]

Tray

Tray

Stacks Free of Misalignment

Stacks Subject to Misalignment

[1] Stack

[4] Variation present among lead edges of sheets

[2] Tray auxiliary plate

[5] Variation absent among trail edges of sheets

[3] Processing stopper

F-2-27

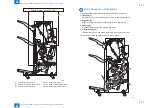

3) Stack delivery roller rotates in the direction of the arrow and the paper is pushed to the

operation stopper. At this time, belt change lever shifts in the direction of the arrow to avoid

the contact with the paper.

Also the position of the operation stopper is adjusted to front/rear depending on the paper

size.

[1]

[2]

[3]

[5]

[4]

F-2-28

Содержание Booklet Finisher-D1

Страница 12: ... Notes Before Servicing Points to Note at Cleaning Safety Precautions ...

Страница 14: ...1 1 Product Outline Product Outline Product Specifications Names of Parts ...

Страница 60: ...3 3 Periodic Servicing Periodic Servicing User Maintenance Maintenance and Inspection ...

Страница 177: ...5 5 Adjustment Adjustment Basic Adjustment Adjustment at Time of Parts Replacement Auxiliary Adjustment ...

Страница 315: ...6 6 Troubleshooting Troubleshooting Upgrading ...

Страница 357: ... Service Tools Solvents and Oils List of Signals General Circuit Diagram Appendix ...