MT2136

3-1

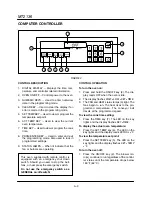

STANDARD CONTROL OPTIONS

U.E. TEMPERATURE CONTROLLER WITH OPEN LOOP DC DRIVE SYSTEM

7

TEMPERATURE

ON

OFF

HEAT

ON

OFF

BLOWER

6

COOK TIME

ON

OFF

CONVEYOR

1

5

3

4

2

FIGURE 1

CONTROL DESCRIPTION

1. COOK TIME DISPLAY

- Gives the belt speed.

2. CONVEYOR ADJUSTMENT KNOB - Turn to

adjust the conveyor speed.

3. TEMPERATURE CONTROL KNOB - Turn to

set cook temperature.

4. HEAT LIGHT - Indicates the control is calling

for heat.

5. HEAT SWITCH - Controls power to the burner.

6. BLOWER SWITCH - Controls power to the

blowers.

7. CONVEYOR SWITCH - Controls power to the

conveyor motor.

CONTROL OPERATION

1. Turn the manual gas valve to the

OPEN

posiĆ

tion. This is only necessary on initial startĆup.

2. Turn the BLOWER SWITCH (6) to

ON

.

3. Push and turn the TEMPERATURE CONTROL

KNOB (3) clockwise to the desired setting.

4. Turn the HEAT SWITCH (5) to

ON

. The burner

purge timer will be energized. After approxiĆ

mately thirty (30) seconds, a spark ignites the

burner. Initial start may require longer due to air

in the gas line.

NOTE: If the oven fails to ignite after the thirty

(30) second purge, turn the HEAT

SWITCH (

5)

to OFF and wait 5 minutes

before turning back to ON.

5. Turn the CONVEYOR SWITCH (7) to

ON

. The

conveyor belt starts to travel through the oven.

This circuit is independent and can be turned

on or off without affecting any other operaĆ

tions. Adjust the conveyor speed as follows:

Turn the ADJUSTMENT KNOB (2) clockwise to

increase speed, counterĆclockwise to deĆ

crease speed. Turn the knobĆlock behind the

control knob to hold the desired belt speed

6. Turn the BLOWER (6), CONVEYOR (7) and

HEAT (8) SWITCHES to

OFF

. The Cool Down

circuit is energized. The blower motor(s) conĆ

tinue to run until the oven temperature is beĆ

tween 135-170

F (57-77

C). The digital

temperature display remains lit until the cool

down circuit deĆenergizes.

The oven will hold these parameters daily and will

require no further adjustments unless a different

product is placed in the oven.

NOTE: Each oven contains different components

and must be adjusted individually.

Содержание MT2136 Series

Страница 4: ...INTRODUCTION CHAPTER 1 ...

Страница 15: ...MT2136 1 11 35 30 35 29 39 28 38 33 34 31 37 36 26 27 32 EXTERIOR COMPONENTS FIGURE 3 ...

Страница 17: ...MT2136 1 13 CE GAS BURNER COMPONENTS Control Box not Shown 16 17 FIGURE 5 ...

Страница 18: ...INTRODUCTION 1 14 CONTROL PLATE ASSEMBLY 18 25 16 26 21 19 20 24 23 22 EXCLUSIVE TO CE 40 41 42 43 FIGURE 6 ...

Страница 19: ...MT2136 1 15 This page intentionally left blank ...

Страница 20: ...ASSEMBLY CHAPTER 2 ...

Страница 23: ...MT2136 2 3 This page intentionally left blank ...

Страница 24: ...OPERATION CHAPTER 3 ...

Страница 49: ...MT2136 3 25 16 17 18 19 20 21 12 13 13 13 4 7 15 3 2 1 14 8 9 10 6 11 5 5 FIGURE 4 ...

Страница 50: ...OPERATION 3 26 16 17 20 19 18 15 3 12 13 13 13 4 14 7 1 2 8 9 10 6 11 5 5 FIGURE 5 ...

Страница 51: ...MT2136 3 27 22 23 24 25 26 21 19 18 18 18 4 7 1 3 2 20 5 5 11 12 13 14 15 16 8 17 6 9 10 FIGURE 6 ...

Страница 52: ...OPERATION 3 28 25 26 27 29 28 2 24 23 22 21 21 21 3 1 7 20 4 16 17 18 19 14 15 8 10 6 11 12 13 9 5 5 FIGURE 7 ...

Страница 53: ...MT2136 3 29 1 17 3 2 4 16 16 16 15 21 5 13 14 14 10 18 19 6 7 8 20 9 12 11 FIGURE 8 ...

Страница 54: ...OPERATION 3 30 1 18 16 16 16 16 17 15 22 5 3 2 4 13 10 19 20 6 7 8 21 9 12 11 14 14 FIGURE 9 ...

Страница 55: ...MT2136 3 31 1 21 21 21 17 16 22 18 20 19 14 3 2 4 11 6 13 12 15 10 7 8 9 5 FIGURE 10 ...

Страница 56: ...OPERATION 3 32 1 8 8 8 8 6 7 16 15 17 18 3 2 4 11 5 9 9 12 13 14 FIGURE 11 ...

Страница 57: ...MT2136 3 33 1 6 9 8 19 22 21 7 16 17 2 3 4 18 5 10 14 20 12 11 13 15 25 25 25 24 FIGURE 12 ...

Страница 58: ...OPERATION 3 34 1 FIGURE 13 ...

Страница 60: ...CALIBRATION AND ADJUSTMENT CHAPTER 4 ...

Страница 77: ...MT2136 4 17 This page intentionally left blank ...

Страница 78: ...TROUBLESHOOTING CHAPTER 5 ...

Страница 86: ...TECHNICAL APPENDIX CHAPTER 6 ...