- 21 -

ELECTRoNIC CoNTRoL/IGNITIoN P.C.B.

The spare electronic control/ignition p.c.b. is set for natural gas.

If the boiler is fed with different gas type, go through the Gas

conversion operations described in the Installation manual.

If an external temperature probe (optional) is fitted, the coef-

ficient K has also to be set as described in the Commission-

ing chapter of the installation manual.

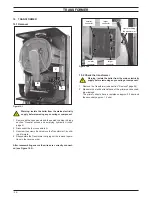

1 Gain access to the parts located inside the control panel as

explained in the section "Control panel" page 5.

2 Remove all the wiring connected to the Electronic control/

ignition p.c.b.

To disconnect the connectors delicately flex the hook present

on one side of each socket.

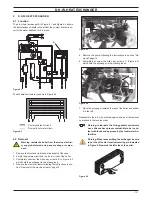

3 Remove the spindles of the c.h. and d.h.w. temperature ad-

justment knobs by delicately pulling them with pliers in the

direction shown by the arrow in Figure 9.13.

figure 9.13

4 Unscrew the four screws that hold the Electronic control/igni-

tion p.c.b. on to the control panel.

5 Remove it by lifting its rear edge and freeing it from any of

the wiring.

6 Re-assemble the Electronic control/ignition p.c.b. following

the removal procedures in the reverse order.

Important

When re-assembling the Electronic control/ignition p.c.b.:

7 It is not necessary to utilise static protections but it is advis-

able to ensure that the p.c.b. is handled with care and held at

the edges and with clean dry hands.

8 Fit the p.c.b. into the control panel by first inserting the front

lower edge under the control knob shafts. Lower the rear

edge and ensure that no wiring is trapped beneath.

9 Insert the spindles in the control panel knobs until the notch A

(Figure 9.14) reaches the potentiometer edge. It is not neces-

sary to force them in the knob.

10 While tightening the screws that fix the Electronic control/igni-

tion p.c.b. on the control panel, keep the p.c.b. towards the

control panel fascia making sure of the contact between the

boiler reset button B and the tab C (Figure 9.14).

figure 9.14

A

A

B

C

Attention

After installing the Electronic control/ignition p.c.b.:

11 Make sure the c.h. (

) and d.h.w. (

) temperature ad-

justment knobs can move freely for the complete range.

If not, remove the spindle again as described at step 3, turn

the knob half a turn and re-insert the spindle.

12 Make sure that the settings comply with the indications given

in section "Setting the boiler control function modes" page 19.

13 Operate the boiler and close the gas inlet cock so that the

boiler goes into the safety lock-out state.

Verify the correct operation of the boiler reset button by

pressing and releasing it.

Warning: After cleaning or replacement as detailed

above, if it deemed necessary to undertake a com-

bustion analysis as detailed in section "Removal"

page 28.