36

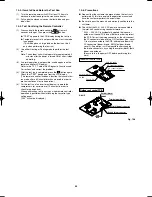

(5) Use shielded wires for inter-unit control wiring (c) and

ground the shield on one side, otherwise misoperation

from noise may occur. (Fig. 5-6)

Connect wiring as shown in Section “5-3. Wiring System

Diagrams”.

Shielded wire

Ground

Fig. 5-6

WARNING

Loose wiring may cause the terminal to overheat or result

in unit malfunction. A fire hazard may also occur. Therefore,

ensure that all wiring is tightly connected.

When connecting each power wire to the terminal, follow the

instructions on “How to connect wiring to the terminal” and

fasten the wire securely with the terminal screw.

How to connect wiring to the terminal

■

For stranded wires

(1) Cut the wire end with cutting pliers, then strip the insulation

to expose the stranded wire about 10 mm and tightly twist

the wire ends. (Fig. 5-7)

Stranded wire

Strip 10 mm

Ring

pressure

terminal

Fig. 5-7

(2) Using a Phillips head screwdriver, remove the terminal

screw(s) on the terminal plate.

(3) Using a ring connector fastener or pliers, securely clamp

each stripped wire end with a ring pressure terminal.

(4) Put the removed terminal screw through the ring pressure

terminal and then replace and tighten the terminal screw

using a screwdriver. (Fig. 5-8)

Ring

pressure

terminal

Special

washer

Screw

Terminal plate

Ring pressure

terminal

Wire

Wire

Screw and

Special washer

Fig. 5-8

6. HOW TO INSTALL THE TIMER REMOTE

CONTROLLER (OPTIONAL PART)

NOTE

Refer to the Instruction Manual attached to the optional Timer

Remote Control Unit.

7. HOW

TO

PROCESS

TUBING

The liquid tubing side is connected by a flare nut, and the gas

tubing side is connected by brazing.

7-1. Connecting the Refrigerant Tubing

Use of the Flaring Method

Many of conventional split system air conditioners employ the

flaring method to connect refrigerant tubes that run between

indoor and outdoor units. In this method, the copper tubes are

flared at each end and connected with flare nuts.

Flaring Procedure with a Flare Tool

(1) Cut the copper tube to the required length with a tube

cutter. It is recommended to cut approx. 30 – 50 cm longer

than the tubing length you estimate.

(2) Remove burrs at each end of the copper tubing with a

tube reamer or file. This process is important and should

be done carefully to make a good flare. Be sure to keep

any contaminants (moisture, dirt, metal filings, etc.) from

entering the tubing. (Figs. 7-1 and 7-2)

After

Before

Deburring

Copper

tubing

Reamer

Fig. 7-1

Fig. 7-2

NOTE

When reaming, hold the tube end downward and be sure that

no copper scraps fall into the tube. (Fig. 7-2)

(3) Remove the flare nut from the unit and be sure to mount it

on the copper tube.

(4) Make a flare at the end of the copper tube with a flare tool.

(Fig. 7-3)

Flare nut

Copper

tubing

Flare tool

Fig. 7-3

NOTE

A good flare should have the following characteristics:

●

inside surface is glossy and smooth

●

edge is smooth

●

tapered sides are of uniform length

Flare size: A (mm)

A

Copper tubing

(Outer dia.)

A

0

– 0.4

ø6.35

9.1

ø9.52

13.2

ø12.7

16.6

ø15.88

19.7

Airwell̲PAC-i̲eng.indb 36

Airwell̲PAC-i̲eng.indb 36

2009/07/09 16:13:29

2009/07/09 16:13:29

Содержание OU-PSINV-25HR

Страница 75: ...75 ...