17

Smooth Radius

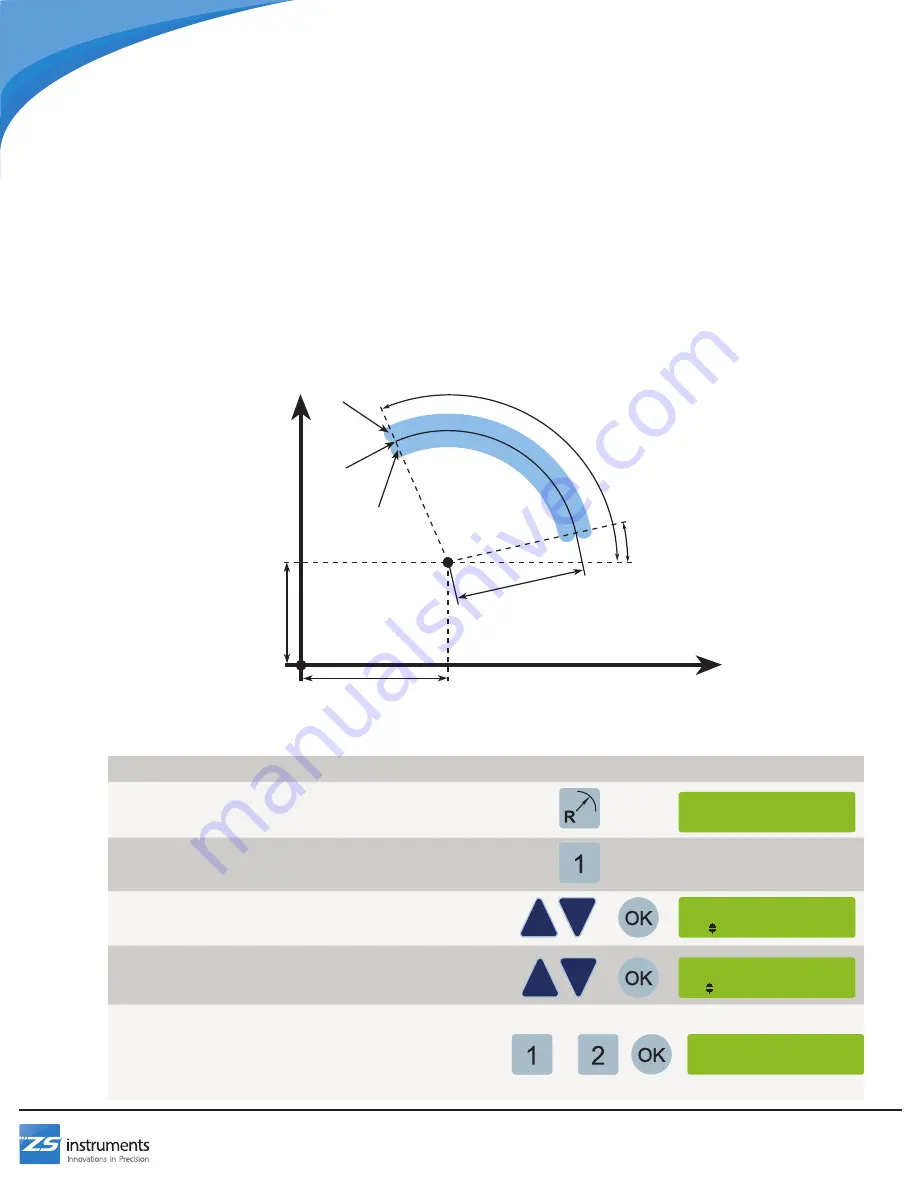

To machine a radius or rounded feature in any plane, use the Smooth Radius feature. When machining a Smooth Radius

feature the digital readout will sequentially display the coordinates of the two axes where the tool needs to be positioned

to create the curved surface. This program requires the following inputs:

• The cut plane of the radius (XY, YZ, or XZ)

• Whether the cut will be external or internal

• The position of the center point of the radius

• The starting and ending angles (counterclockwise from the three o’ clock position)

• The radius of the feature

• The maximum cut size (smaller number produces smoother result but requires more machining steps)

The Smooth Radius feature can be saved to one of 99 slots or it can be run immediately without saving

Note: A ball end mill MUST be used when milling radii on the XZ or YZ planes.

To Create a New Smooth Radius Feature:

Step

Buttons

Information Screen

1 Press the radius button to access the smooth radius

feature

2 Press 1 to setup a new smooth radius program

3 Select a cut plane using the up and down arrows, then

press OK to confirm

4 Use the up and down arrows to select whether the cut

will be internal or external

Press OK to confirm

5 Enter the center point of the radius for each axis:

Press 1 to sense the current position

OR

Press 2 to enter the position using the numpad

Press OK to confirm

*SMOOTH RADIUS*

1-New 2-Load

Cut Plane

1 XY

Cut direction

1 External

Mill Functions

X Center

Y Center

Start Angle

End Angle

Radius

External

Cut

Internal

Cut

Edge of Cut

Y Axis

X Axis

Datum

OR

X Center

1-Sense 2-Enter