88 / 96

CAYMAN

Version 01 - Revision 00

09/05/2017

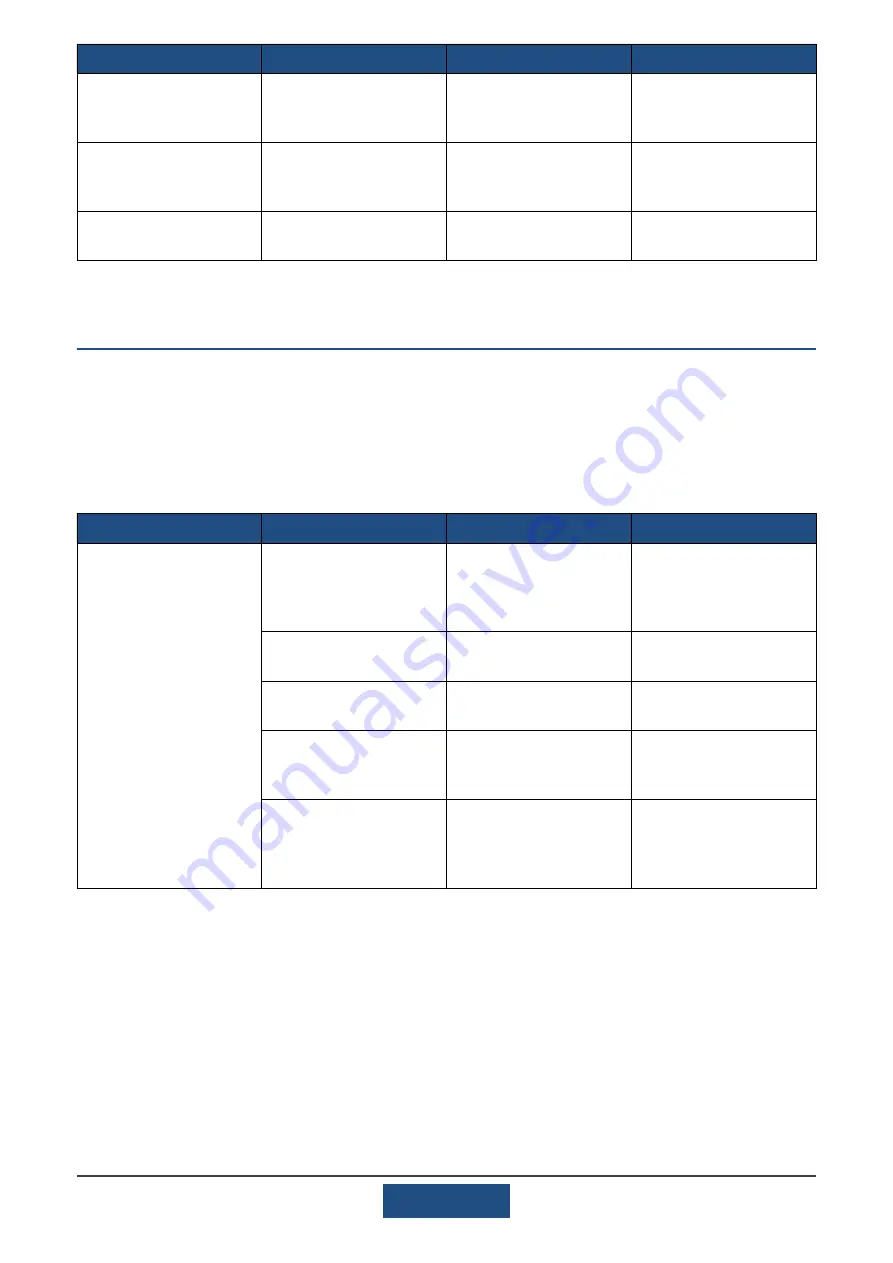

Components

type of operation

frequency

reference

Rotating head

Changing the hydraulic

motor oil

Yearly

Rotating head

Slewing ring bolts repla-

cement

Biannually

Rotating head

Checking the state of the

speed valve

Biannually

tab. 15

Maintenance frequency summary

7.4

troublEshootING

Should problems arise on the attachment, resolve them by referring to the table below�

For any potential problem envisaged on the equipment, the table below shows:

∂ the cause that generated it;

∂ the solution required to resolve it;

∂ the qualification required to implement the solution�

problem

Cause

solution

qualification required

No power to the upper

jaw�

The machine is not sen-

ding maximum pres-

sure to the attachment

hydraulic system�

Check the machine

hydraulic pressure, refer

to the machine manual;

Mechanical Technician

The speed valve is not

calibrated properly�

Replace the speed valve�

Manufacturer's Techni-

cian

The hydraulic cylinder is

bypassing internally�

Replace the hydraulic

cylinder gaskets�

Manufacturer's Techni-

cian

The swivel hydraulic cou-

pling of the attachment

is bypassing internally�

Replace the swivel

hydraulic coupling ga-

skets�

Manufacturer's Techni-

cian

There is dirt in the oil of

the hydraulic system

(due to quick couplings

or other)�

Repeatedly run the up-

per jaw opening/closing

cycles�

Operator

Summary of Contents for CAYMAN FCE II Series

Page 2: ......

Page 6: ...6 96 CAYMAN Version 01 Revision 00 09 05 2017...

Page 94: ...94 96 CAYMAN Version 01 Revision 00 09 05 2017...

Page 95: ......