4.15 Method 1: Copy One Subtask Job and Create Another Job

4-27

Jobs Not to be Converted

The jobs and relative jobs without group axes cannot be converted.

Group Axes for Conversion

When the group axes for the SOURCE JOB in the multiple group axes system, the axis con-

figuration, etc. of each group axes for SOURCE JOB and DESTINATION JOB must be the

same.

• Robot axis: Same type

• Base axis: Same axis configuration

• Station axis: Same axis configuration

Position Type Variables

The position type variables are not for mirror-shift.

Parameter

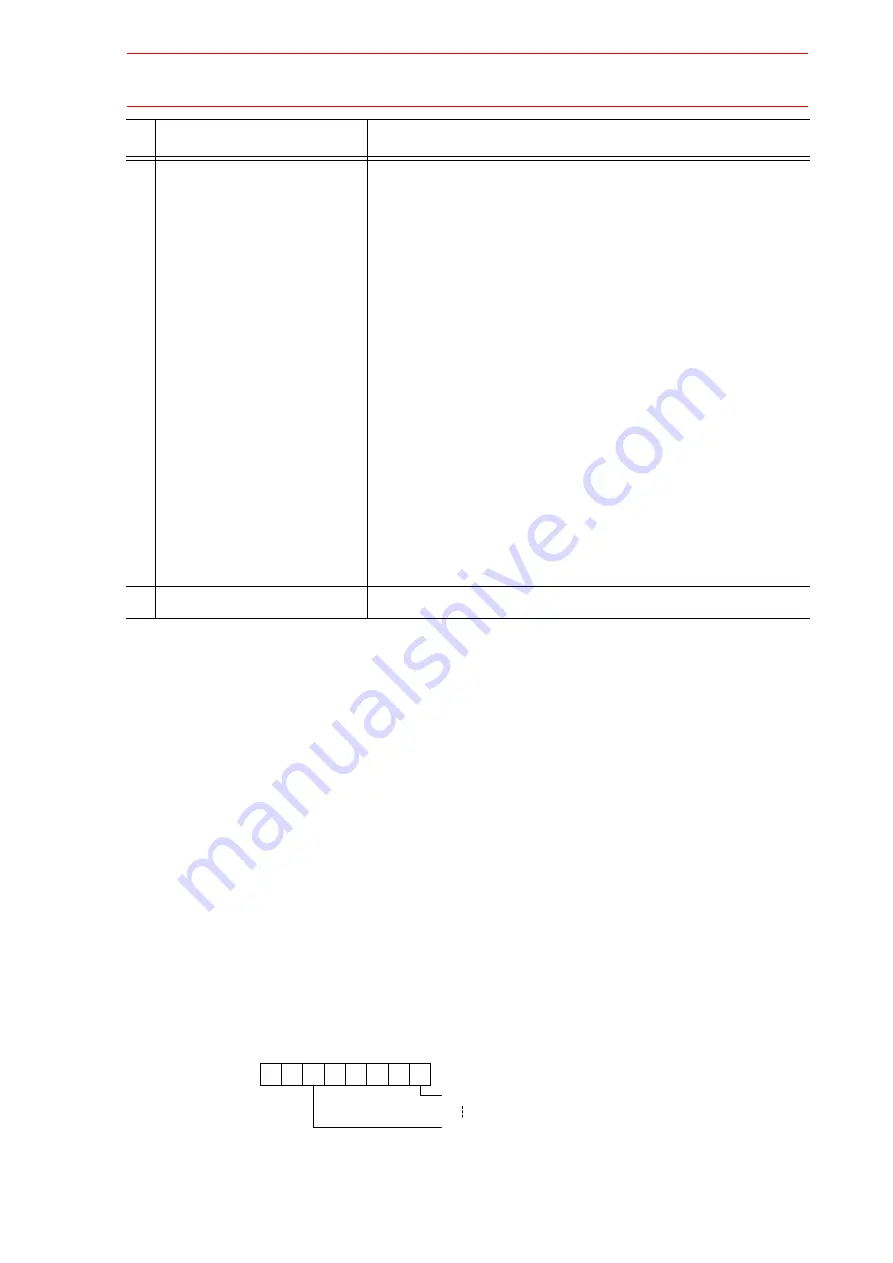

Which axis is to be shifted (reverse the sign) is specified by the following parameter.

S1C

G065: Mirror shift sign reversed axis specification

4

(cont’d)

USER COORD NO.

Specifies the user coordinates number when "USER" is

selected in

. "01" is automatically set as initial value

when the "USER" is selected in

.

This item cannot be set when "PULSE" or "ROBOT" is

selected in

.

TARGET

Specifies the coordinate where conversion is to be done

when "ROBOT" or "USER" is selected in

. "XY," "XZ,"

or "YZ" can be selected. The "XZ" is automatically set as

initial value when "ROBOT" or "USER" is selected in

.

Always specify "XZ" for "ROBOT."

EXECUTE

Executes the conversion. When the conversion destina-

tion job name is entered, the converted job is created

with that name as a new job. When the conversion desti-

nation job name is not entered, the conversion source

job is converted and overwritten.

5

Select "EXECUTE."

Operation

Explanation

1st axis (0: Not reversed, 1: Reversed)

6th axis

T B R

L S

U

91/210