2-16

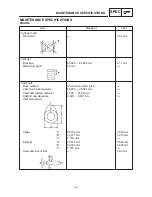

MAINTENANCE SPECIFICATIONS

SPEC

NOTE:

Part to be tightened

Thread size

Tightening

torque

Remarks

g

Nm

m

S

kg

Passenger footrest and frame

Sidestand bracket and frame

Sidestand and sidestand bracket

Sidestand switch

Brake pedal / footrest and frame

Front wheel axle

Front wheel axle pinch bolt

Brake caliper

Brake disc and front wheel

Caliper bleed screw

Rear wheel axle nut

Tension bar and swingarm

Tension bar and brake shoe plate

Brake cam shaft lever

Clutch hub and damper

Final gear case (housing cover)

Bearing housing (final gear case)

Bearing housing (final gear case)

Bearing retainer (final drive pinion gear)

Oil filter bolt (final gear)

Oil drain bolt (final gear)

Housing cover

M8

M10

M10

M5

M6

M16

M8

M10

M8

M7

M14

M8

M8

M6

M10

M10

M8

M10

M65

M14

M14

M10

26

64

56

4

64

59

20

40

23

6

97

20

20

10

62

18

23

23

115

23

23

42

2.6

6.4

5.6

0.4

6.4

5.9

2.0

4.0

2.3

0.6

9.7

2.0

2.0

1.0

6.2

1.8

2.3

2.3

11.5

2.3

2.3

4.2

LH thread

1. First, tighten the ring nut approximately 52 Nm (5.2 m

S

kg) by using the torque wrench, then loosen

the ring nut completely.

2. Retighten the ring nut to specification.

Summary of Contents for XVS6501997

Page 1: ......

Page 2: ......

Page 8: ......

Page 10: ...GEN INFO ...

Page 18: ...GEN INFO ...

Page 20: ...SPEC ...

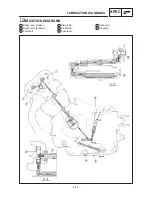

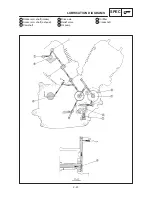

Page 44: ...2 24 LUBRICATION DIAGRAMS SPEC 1 Crankshaft 2 Oil filter 3 Oil pump ...

Page 102: ...INSP ADJ ...

Page 188: ...CARB ...

Page 198: ...CARB ...

Page 266: ...CHAS ...

Page 268: ...ELEC SELF DIAGNOSIS 7 49 TROUBLESHOOTING 7 50 ...

Page 298: ...E 7 30 SIGNAL SYSTEM ELEC EB806000 SIGNAL SYSTEM CIRCUIT DIAGRAM ...

Page 320: ...TRBL SHTG ...

Page 326: ...TRBL SHTG ...