4-63

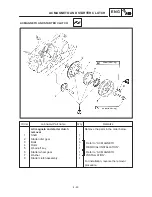

CRANKSHAFT AND CONNECTING RODS

ENG

NOTE:

36 Nm (3.6 m

kg)

NOTE:

CAUTION:

NOTE:

5. Install:

Connecting rod cap

1

Be sure that the characters

a

on the side of the

cap and connecting rod are aligned.

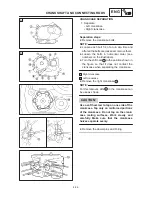

6. Tighten:

Nuts (connecting rod cap)

Apply molybdenum disulfide grease to the rod

cap bolt threads and nut surfaces.

When tightening the nuts be sure to use

an F-type torque wrench.

Without pausing tighten to full torque

specification. Apply continuous torque

between 3.0 and 3.6 m

kg. Once you reach

3.0 m

kg DO NOT STOP TIGHTENING un-

til final torque is reached. If the tightening

is interrupted between 3.0 and 3.6 m

kg,

loosen the nut to less than 3.0 m

kg and

start again.

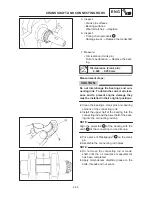

7. Install:

Crankshaft

1

Align the left connecting rod with the rear cylin-

der sleeve hole.

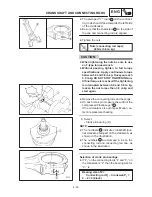

CRANKCASE ASSEMBLY

1. Apply:

Engine oil

(onto the main journal bearings)

Sealant

(onto the crankcase mating surfaces)

Yamaha Bond No.1215:

90890-85505

Summary of Contents for XVS6501997

Page 1: ......

Page 2: ......

Page 8: ......

Page 10: ...GEN INFO ...

Page 18: ...GEN INFO ...

Page 20: ...SPEC ...

Page 44: ...2 24 LUBRICATION DIAGRAMS SPEC 1 Crankshaft 2 Oil filter 3 Oil pump ...

Page 102: ...INSP ADJ ...

Page 188: ...CARB ...

Page 198: ...CARB ...

Page 266: ...CHAS ...

Page 268: ...ELEC SELF DIAGNOSIS 7 49 TROUBLESHOOTING 7 50 ...

Page 298: ...E 7 30 SIGNAL SYSTEM ELEC EB806000 SIGNAL SYSTEM CIRCUIT DIAGRAM ...

Page 320: ...TRBL SHTG ...

Page 326: ...TRBL SHTG ...