4-58

STEERING HEAD

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

NOTE:

• Always replace the bearings and bearing

races as a set.

• Whenever the steering head is disassem-

bled, replace the dust seal.

4. Check:

• Upper bracket

• Lower bracket

(along with the steering stem)

• Bends/cracks/damage

→

Replace.

EAS00683

INSTALLING THE STEERING HEAD

1. Lubricate:

• Upper bearing

• Lower bearing

• Bearing races

Recommended lubricant

Lithium-soap-based grease

2. Install:

• Lower ring nut

3. Adjust:

• Steering head

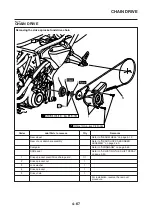

a. Tighten the lower ring nut “1” to the specified

torque with a steering nut wrench “2”.

NOTE:

Set the torque wrench at a right angle to the

steering nut wrench.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Steering nut wrench

90890-01403

Lower ring nut

(initial tightening torque)

52 Nm (5.2 m·kg, 38 ft·lb)

b. Loosen the lower ring nut completely, and

then tighten it to the specified torque.

WARNING

Do not overtighten the lower ring nut.

Lower ring nut

(final tightening torque)

18 Nm (1.8 m·kg, 13 ft·lb)

c. Check the steering head for looseness or

binding by turning the front fork all the way

in both directions. If any binding is felt, re-

move the lower bracket and check the up-

per and lower bearings.

Refer to “CHECKING THE STEERING

HEAD”.

d. Install the rubber washer “2”.

e. Install the upper ring nut “3”.

f. Finger tighten the upper ring nut “3”, and

then align the slots of both ring nuts. If nec-

essary, hold the lower ring nut and tighten

the upper ring nut until their slots are

aligned.

g. Install the lock washer “1”.

NOTE:

Make sure the lock washer tabs “a” sit correct-

ly in the ring nut slots “b”.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

4. Install:

• Upper bracket

• Washer

• Steering stem nut

5. Install:

• Front fork legs

Refer to “INSTALLING THE FRONT FORK

LEGS”.

NOTE:

Temporarily tighten the lower bracket pinch

bolts.

Summary of Contents for MT-03

Page 7: ......

Page 9: ......

Page 25: ......

Page 53: ...2 28 COOLING SYSTEM DIAGRAMS 1 2 3 4 5 6 7 8 9 5 10 11 A B C ...

Page 56: ...2 31 LUBRICATION CHART Pressure feed Splashed scavenge ...

Page 57: ...2 32 LUBRICATION DIAGRAMS LUBRICATION DIAGRAMS A A 1 3 2 2 4 A A A A ...

Page 59: ...2 34 LUBRICATION DIAGRAMS A A A A 3 1 2 3 4 ...

Page 60: ...2 35 LUBRICATION DIAGRAMS 1 Oil delivery pipe 2 2 Oil delivery pipe 1 3 Oil filter 4 Oil pump ...

Page 61: ...2 36 LUBRICATION DIAGRAMS 1 7 2 3 4 5 6 A ...

Page 63: ...2 38 LUBRICATION DIAGRAMS 1 6 5 4 3 2 ...

Page 65: ...2 40 CABLE ROUTING CABLE ROUTING ...

Page 67: ...2 42 CABLE ROUTING ...

Page 69: ...2 44 CABLE ROUTING ...

Page 71: ...2 46 CABLE ROUTING ...

Page 73: ...2 48 CABLE ROUTING ...

Page 75: ...2 50 CABLE ROUTING ...

Page 77: ...2 52 CABLE ROUTING ...

Page 79: ...2 54 CABLE ROUTING ...

Page 81: ...2 56 CABLE ROUTING ...

Page 83: ...2 58 CABLE ROUTING ...

Page 85: ...2 60 CABLE ROUTING ...

Page 87: ......

Page 121: ......

Page 177: ...4 54 FRONT FORK WARNING Make sure the brake hoses are routed prop erly ...

Page 271: ......

Page 273: ......

Page 287: ......

Page 325: ......

Page 339: ...8 12 CHARGING SYSTEM 2 A C magneto 5 Rectifier regulator 7 Battery 8 Main fuse ...

Page 341: ...8 14 CHARGING SYSTEM ...

Page 355: ...8 28 COOLING SYSTEM ...

Page 365: ...8 38 IMMOBILIZER SYSTEM ...

Page 366: ...8 39 ELECTRICAL COMPONENTS EAS27970 ELECTRICAL COMPONENTS ...

Page 368: ...8 41 ELECTRICAL COMPONENTS ...

Page 370: ...8 43 ELECTRICAL COMPONENTS EAS27980 CHECKING THE SWITCHES ...

Page 389: ......

Page 391: ......

Page 397: ...COLOR CODE ...

Page 398: ......

Page 399: ...YAMAHA MOTOR ITALIA S P A ...

Page 400: ...MT 03 2006 WIRING DIAGRAM ...