POWR

5-43

6D45F11

Power unit

NOTE:

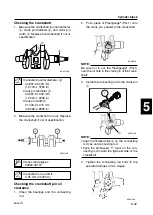

Do not turn the connecting rod until the crank

pin oil clearance measurement has been

completed.

5.

Remove the connecting rod cap and

measure the width of the compressed

Plastigauge

®

(PG-1) on each crank pin.

Replace the connecting rod.

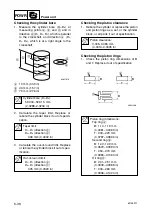

Checking the crankshaft

main journal oil clearance

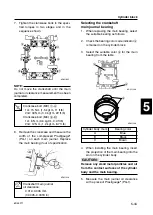

1.

Clean the bearings, main journals, and

bearing portions of the crankcase and

cylinder body.

2.

Place the cylinder body upside down on

a bench.

3.

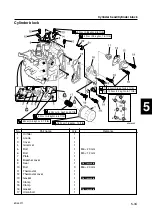

Install half of the bearings

1

and the

crankshaft

2

into the cylinder body

3

.

3

2

1

a

6D451300

6D451370

Connecting rod bolt:

1st: 10 N·m (1.0 kgf·m, 7.2 ft·lb)

2nd: 22 N·m (2.2 kgf·m, 16 ft·lb)

Crank pin oil clearance:

0.021–0.045 mm

(0.0008–0.0018 in)

c

C

Install the bearings in their original posi-

tions.

NOTE:

Insert the projection

a

of the bearing into the

notch in the cylinder body.

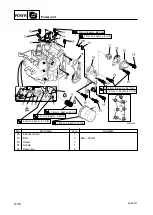

4.

Put a piece of Plastigauge

®

(PG-1) on

each main journal parallel to the crank-

shaft.

NOTE:

Do not put the Plastigauge

®

(PG-1) over the

oil hole in the main journals of the crankshaft.

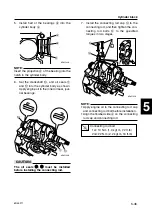

5.

Install the remaining half of the bearings

into the crankcase.

NOTE:

Insert the projection of the bearing into the

notch in the crankcase.

6.

Install the crankcase onto the cylinder

body and apply engine oil onto the

threads of the crankcase bolts.

6D451310

6D45F11-05 03.10.9 20:44 Page 46