6D45F11

5-42

9

8

7

6

5

4

3

2

1

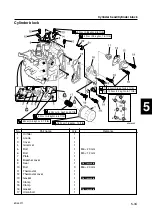

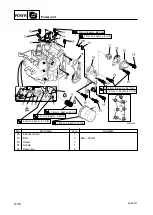

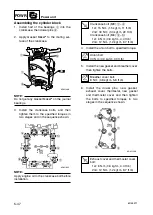

Cylinder block

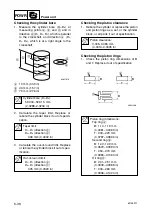

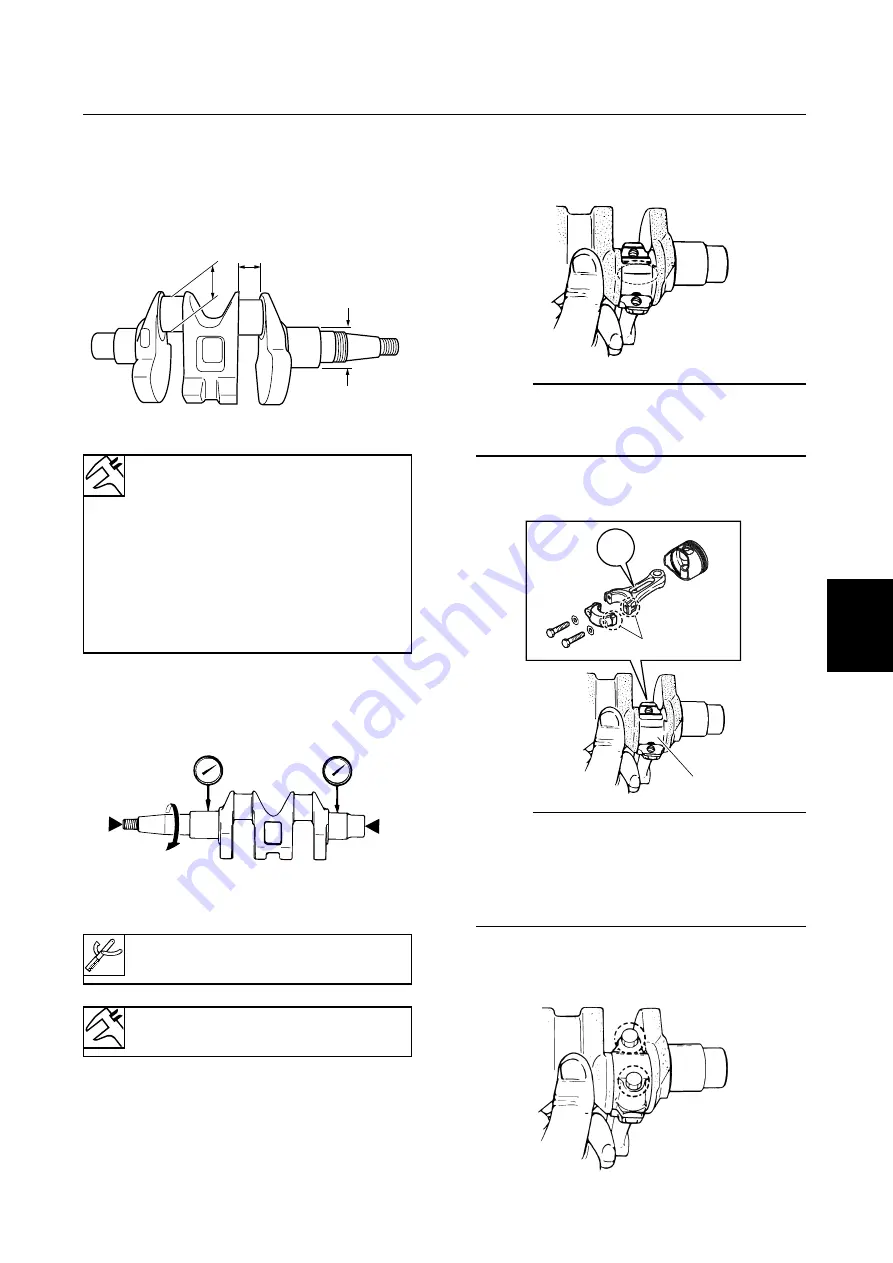

Checking the crankshaft

1.

Measure the crankshaft journal diameter

a

, crank pin diameter

b

, and crank pin

width

c

. Replace the crankshaft if out of

specification.

2.

Measure the crankshaft run-out. Replace

the crankshaft if out of specification.

Checking the crankshaft pin oil

clearance

1.

Clean the bearings and the connecting

rod.

2.

Put a piece of Plastigauge

®

(PG-1) onto

the crank pin, parallel to the crankshaft.

NOTE:

Be sure not to put the Plastigauge

®

(PG-1)

over the oil hole in the crank pin of the crank-

shaft.

3.

Install the connecting rod to the crank pin

1

.

NOTE:

9

Align the finished side

a

on the connecting

rod cap and connecting rod.

9

Face the embossed “Y” mark on the con-

necting rod toward the flywheel side of the

crankshaft.

4.

Tighten the connecting rod bolts to the

specified torques in two stages.

b

c

a

6D451280

6D451290

Crankshaft journal diameter

a

:

34.997–35.009 mm

(1.3778–1.3783 in)

Crank pin diameter

b

:

30.997–31.009 mm

(1.2204–1.2208 in)

Crank pin width

c

:

21.000–21.070 mm

(0.8268–0.8295 in)

Crank stand aligner:

90890-03107

Crankshaft run-out limit:

0.05 mm (0.0020 in)

6D451340

Y

a

1

6D451350

6D451360

6D45F11-05 03.10.9 20:44 Page 45