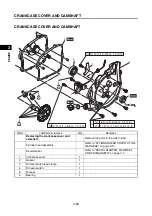

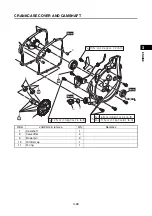

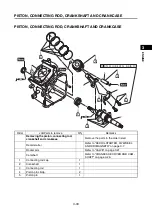

PISTON, CONNECTING ROD, CRANKSHAFT AND CRANKCASE

3-39

1

2

3

4

5

6

7

8

9

10

EN

GIN

E

CHECKING THE CRANKSHAFT

1.

Check:

• Crankshaft sprocket “1”

Crack/damage/wear

Replace the crankshaft.

2.

Measure:

• Crankshaft runout limit

Out of specification

Replace.

Use a dial gauge.

3.

Measure:

• Crank pin outside diameter “a”

Out of specification

Replace.

Use a micrometer.

CHECKING THE CONNECTING ROD OIL

CLEARANCE

TIP

Measure the oil clearance if replacing the crankshaft or

connecting rod.

1.

Place a piece of Plastigauge® “1” on the crank pin

horizontally.

TIP

Wipe off oil thoroughly from the crankshaft, connecting

rod, and connecting rod cap.

1

Dial indicator gauge:

YU-A8428

Dial gauge:

90890-03097

Runout limit:

0.03 mm (0.0012 in)

a

Crank pin outside diameter:

21.969–21.984 mm (0.8649–0.8655 in)

Limit:

21.939 mm (0.8637 in)

1

Summary of Contents for EF2200iS

Page 2: ...7PC F8197 E0_Hyoshi indd 3 4 2019 08 28 16 31 47 ...

Page 18: ...SPECIAL TOOLS AND TESTERS 1 8 1 2 3 4 5 6 7 8 9 10 GENERAL INFORMATION MEMO ...

Page 50: ...PERIODIC MAINTENANCE 2 32 1 2 3 4 5 6 7 8 9 10 PERIODIC CHECKS AND ADJUSTMENTS MEMO ...

Page 99: ...FUEL PUMP 4 7 1 2 3 4 5 6 7 8 9 10 CARBURETOR MEMO ...

Page 116: ...ELECTRICAL COMPONENTS 5 17 1 2 3 4 5 6 7 8 9 10 ELECTRICAL MEMO ...

Page 138: ...WIRE ROUTING DIAGRAM 7 16 1 2 3 4 5 6 7 8 9 10 SPECIFICATIONS ENGINE AND GENERATOR ...

Page 140: ...WIRE ROUTING DIAGRAM 7 18 1 2 3 4 5 6 7 8 9 10 SPECIFICATIONS UPPER SIDE AND LEFT SIDE VIEW ...

Page 142: ...WIRE ROUTING DIAGRAM 7 20 1 2 3 4 5 6 7 8 9 10 SPECIFICATIONS CONTROL UNIT ...

Page 144: ...WIRE ROUTING DIAGRAM 7 22 1 2 3 4 5 6 7 8 9 10 SPECIFICATIONS GENERATOR ...

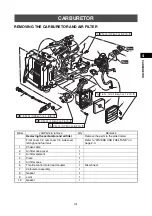

Page 148: ...WIRE ROUTING DIAGRAM 7 26 1 2 3 4 5 6 7 8 9 10 SPECIFICATIONS CARBURETOR AND AIR FILTER ...

Page 150: ...WIRE ROUTING DIAGRAM 7 28 1 2 3 4 5 6 7 8 9 10 SPECIFICATIONS FUEL TANK AND FUEL HOSES ...

Page 152: ...WIRE ROUTING DIAGRAM 7 30 1 2 3 4 5 6 7 8 9 10 SPECIFICATIONS ...

Page 160: ...MEMO ...

Page 161: ...7PC F8197 E0_Hyoshi indd 3 4 2019 08 28 16 31 47 ...