630140_1

XFIRE_1200_GB_Manual_R

‐

emotion

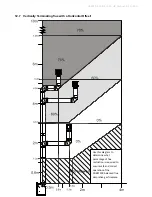

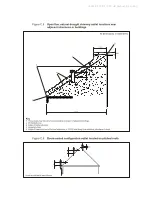

12.11 Sealing ‘through roof’ and ‘through wall’ penetrations:

For ‘through roof’ penetrations, use a Master Flash flashing or equivalent to create a

weather-tight seal between the flue and the roof cladding.

For ‘through wall’ penetrations, this will require the use of a Wall Thimble. The Wall Thimble

will ensure you have suitable clearance from combustibles as well as sealing the

penetration. The section of the wall thimble installed on the external surface of the wall

should be sealed to the wall using a high temperature sealant such as Envirograf Product

62, Sealocrete Heat Resistant Silicone or equivalent. Additional sealant is required to seal

the Terminal Cap to the external wall. A bead should be run along the edge of the Terminal

that will be in contact with the wall once installed.

12.12

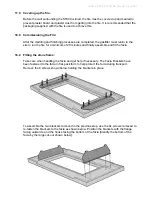

Twist locking procedure:

Before connecting flue components, to ensure an airtight seal run a single 7-8mm bead of

Sealocrete Heat Resistant Silicone, or equivalent, on the ‘male’ end of the flue as

shown in the diagram below.

The four indentations located on the female end of the flue are designed to slide straight

onto the male ends of the adjacent flue length, by orienting the four flue indentations so

they match and slide into the four entry slots on the male ends.

Push the pipe sections completely together, then twist-lock one section clockwise

approximately

one-quarter

turn, until the two sections are fully locked.

Wipe off any excess sealant from the exterior of the flue joint.