1143200

SmartPAC PRO Installation Manual

36

Chapter 2 – Installing SmartPAC PRO

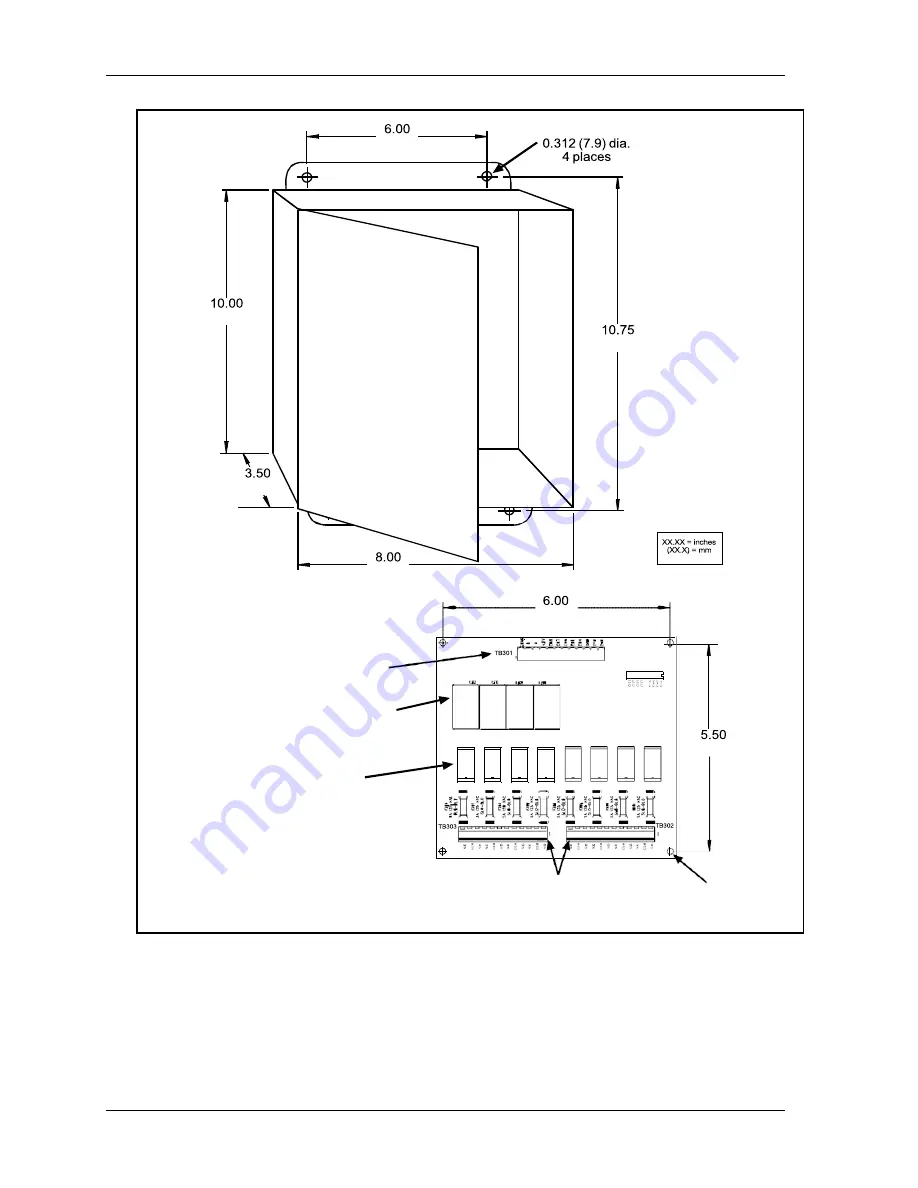

Figure 2-11. ProCamPAC Output Assembly

Cam output

enclosure

(152.4)

(254.0)

(273.1)

(88.9)

(203.2)

(152.4)

Cam output

board

Connections to control

DS301

Sockets for solid state relays

only (Channels 5 through 8)

CH8 CH7 CH6 CH5 CH4 CH3 CH2 CH1

(139.7)

Sockets for

standard relays

(Channels 1

through 8)

NOTE:

For channels 5-8,

plug in standard or

solid state, but not both

CHAN 8 CHAN 7 CHAN 6 CHAN 5

CHAN 4 CHAN 3 CHAN 2 CHAN 1

Terminals for connecting wires to equipment

Clearance hole

for #6 screw

(4 places)

Summary of Contents for SmartPAC PRO

Page 2: ......

Page 4: ......

Page 10: ......

Page 12: ......

Page 14: ......

Page 52: ...1143200 SmartPAC PRO Installation Manual 52 Chapter 2 Installing SmartPAC PRO ...

Page 64: ...1143200 SmartPAC PRO Installation Manual 64 Chapter 8 SmartPAC PRO Fault Messages ...

Page 66: ......

Page 68: ......

Page 70: ......

Page 72: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......