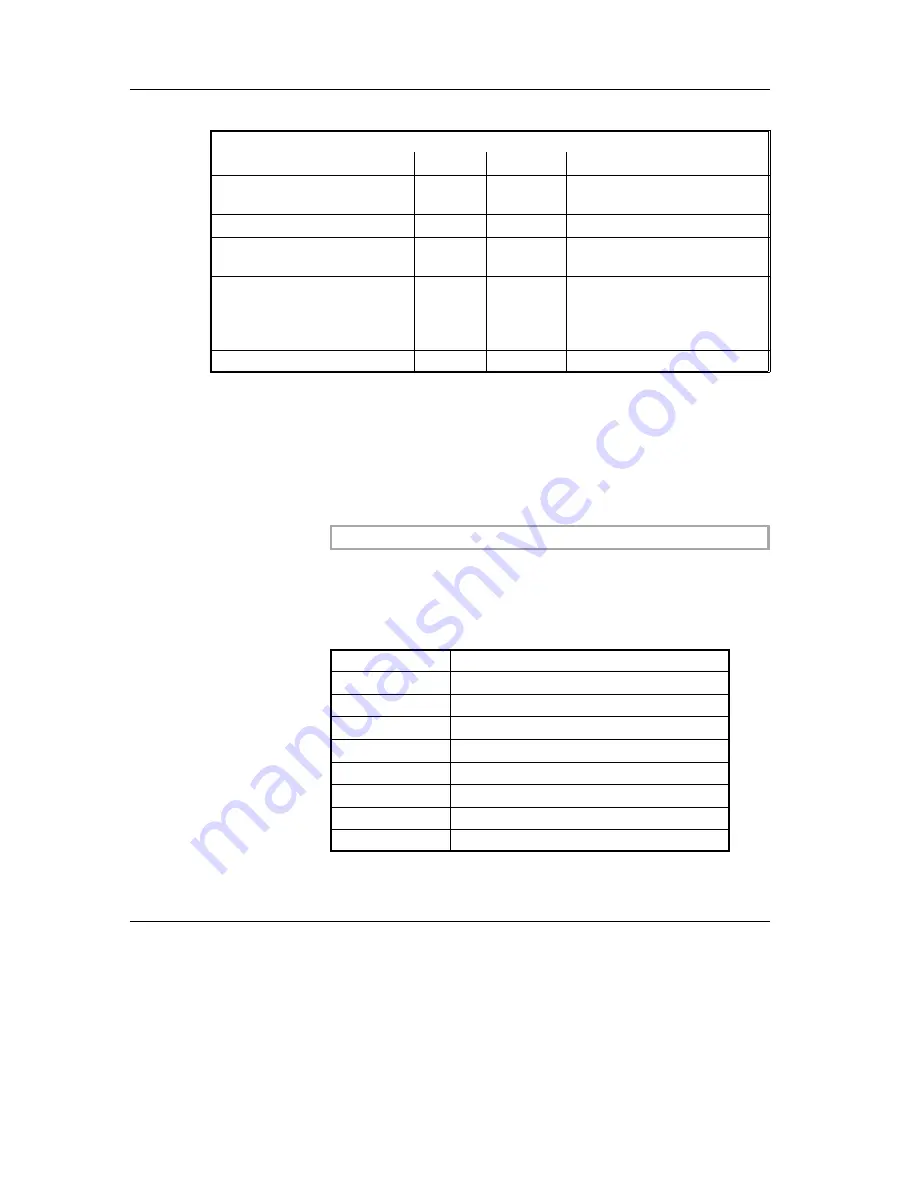

Byte 2

Parameter

Bit

Value

Explanation

Wide print

0

0

1

switched off

switched on

-

1

undefined

Unidirectional printing

2

0

1

switched off

switched on

selected

station

4, 3

00

01

10

11

Journal

Receipt & Journal

Receipt

Document

-

7, 6, 5

fixed 111

not used

Byte No.: 3 Bit 0-3 : international character set

(see ESC R)

Bit 4-7 : not used, fixed 0000

Byte No.: 4 Print stop sensors

(see ESC c4)

Byte No.: 5 Waiting time for document insertion

(see ESC f)

Byte No.: 6 Waiting time for restart

(see ESC f)

ESC + 4

The set printer parameters can be read. A data field of 7 bytes (n2 = 7)

with the following meaning is transmitted:

Byte No.: 1 Sensors

Bit

Function

0="1"

Document at start position

1="0"

Document at end position

2="0"

Receipt end

3="0"

Journal end paper roll

4="1"

not used

5="1"

not used

6="1"

not used

7="1"

Unidirectional printing

Description

Control Sequences

GB - 74