e

n

g

li

sh

3. Electroforming bars

17

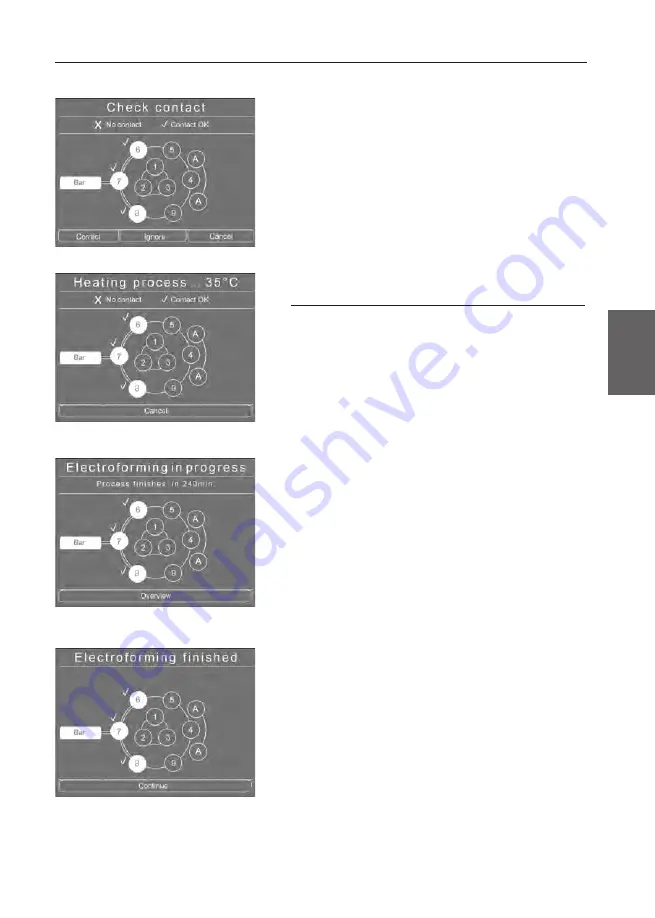

If there is a contact error at positions 6 / 7 / 8 check all

the contacts. All the contacts of the bar fork must be

working to prevent faulty depositions.

3.4.5. Electroforming in progress

(see section 2.4.5.)

3.5. End of processing

(see section 2.5.)

3.5.1 Removing the electroforming cell /

Removing the parts

(see section 2.5.1.)

The unit will start electroforming automatically once

the goldplating bath reaches its operating tempera-

ture. Up until this time you can correct errors (e.g.

poor assembly, wrong layering thickness, wrong

power level) by aborting the process with the

"Cancel" button.

If the deposition process is interrupted, the part cannot

be reused and must be made again with new goldplating

bath, because an interruption may lead to stratification in

the gold layer and loss of firing stability during ceramic

veneering.

Caution: If there is a power failure while the unit is

heating up, it will automatically restart when the

power is restored. During gold deposition a power

cut can be only be bridged for a short time (longer

interruptions lead to stratifications and separation

of the gold layers in ceramic veneers). If a longer

power failure occurs the process stops and the fault

message "F 6" is displayed. Delete the message by

pressing the "Start-Stop" button and the unit

returns to the start-up mode. We do not recommend

the use of parts with a layering thickness of less

than 1.5 mm, as they may be unstable during firing.

New parts should be made.

Important:

!