User Guide

4. Part Replacement

4.14 Chassis Replacement

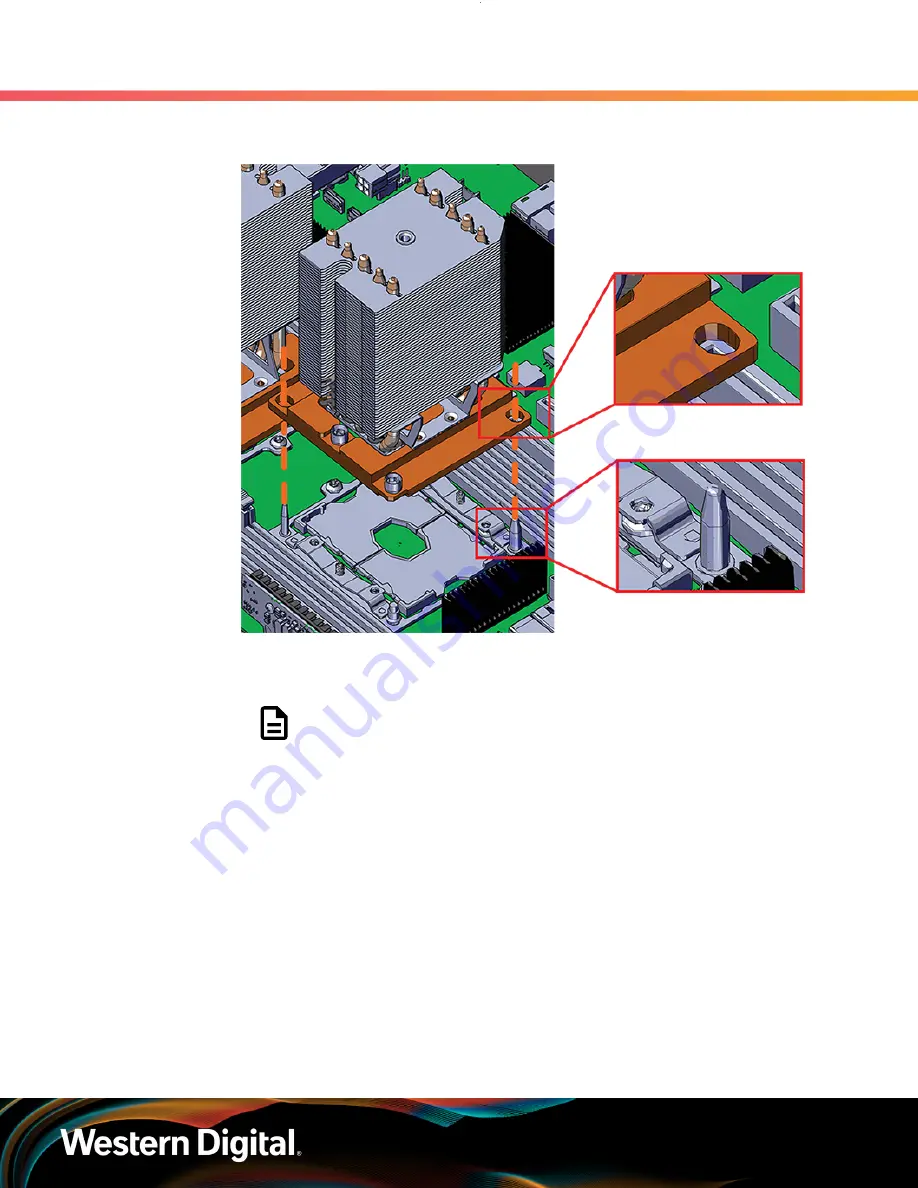

Figure 358:

Heat Sink Alignment Pins

c.

The Heat Sink must be installed by tightening the Torx T30 screws in a specific order. Use

the following diagram to determine the specific order.

Note:

The Heat Sink screws must be tightened to a torque setting of

12in.-lbs. Do not over-tighten. Over-tightening may cause damage to the

parts.

283