409-10042

DT-3000 Machines 1725100-[] and DT-5000 Machines 1725800-[]

Rev E

5 of 22

Tyco Electronics Corporation

2. DESCRIPTION

These machines were designed to be used as a stand–alone semi–automatic bench unit. It is assembled with

metric hardware.

A precision adjustment feature on the machine provides quick and accurate crimp height adjustments. The

batch counter provides a count of the terminations. A work light is included with the machine.

The base plate of Machines –6 and –7 also include a CQM sensor.

These machines accept a wide variety of miniature (mini) quick–change applicators, with minor adjustments,

thus providing a great selection of terminals for many applications. Figure 3 lists changeover cams required to

run 30–mm [1.181–in.] stroke cams (for AMP–O–LECTRIC* Model “K” terminating machines) and 41.28–mm

[1.625–in.] stroke cams (for Model “T” and Model “G” terminating machines) in these machines.

Some heavy-duty mini applicators require special cams that are not listed in Figure 3. Refer to the applicator logs

shipped with the applicators for additional information.

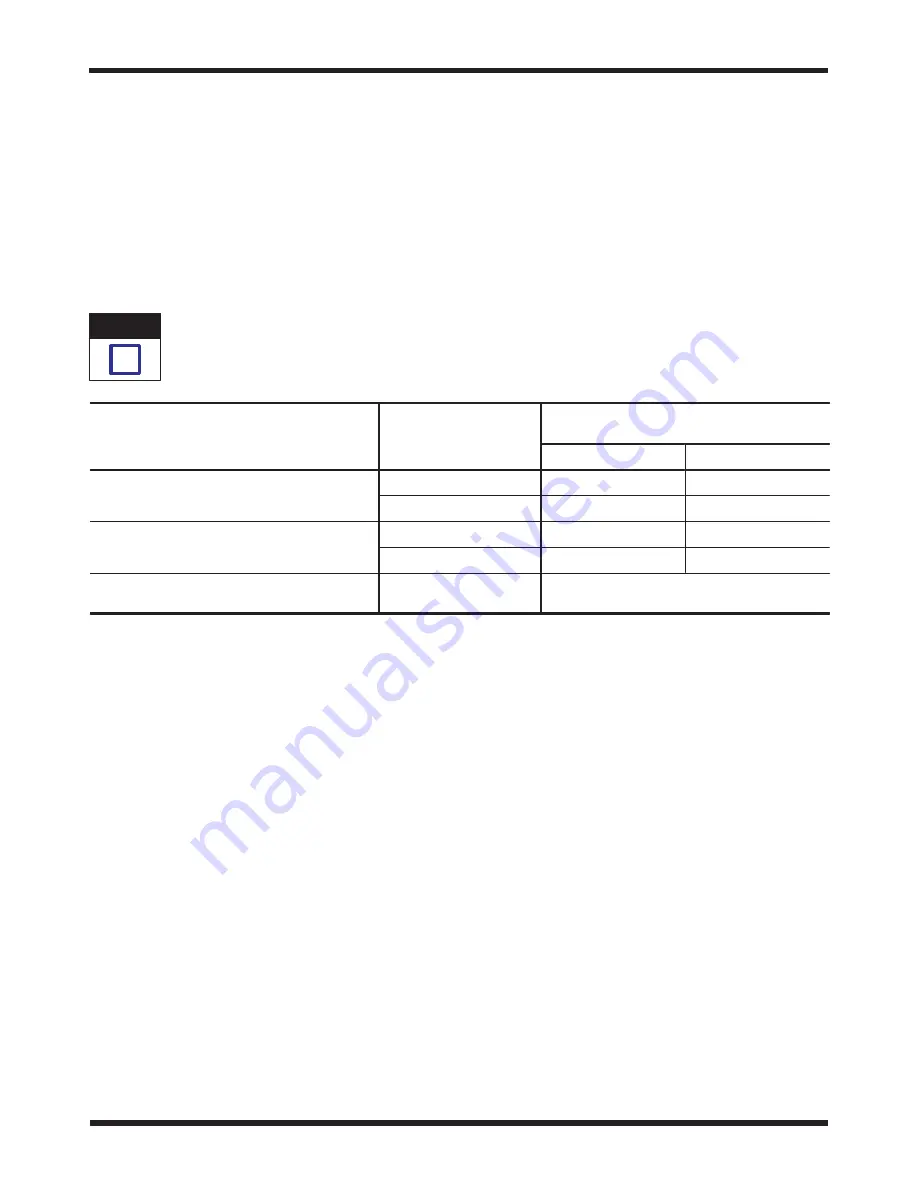

ORIGINAL APPLICATOR

FEED TYPE

CHANGEOVER CAMS

FOR DT-3000 AND DT-5000 MACHINES

ORIGINAL APPLICATOR

FEED TYPE

-2 and -6

-3 and -7

30-mm [1.181-in.] Stroke Applicator for

Pre-Feed

Ċ

690602-6

[

]

pp

Model K" Terminating Machine

Post-Feed

Ċ

690501-4

41.28-mm [1.625-in.] Stroke Applicator for

Pre-Feed

690602-5

Ċ

[

]

pp

Model T" and Model G" Terminating Machines

Post-Feed

690501-3

Ċ

Heavy-Duty Industrial (HD-I) Applicator

Pre-Feed/Post-Feed

Refer to the HD-I Applicator Customer Drawing

For Part Numbers

Figure 3

Quick–Disconnect Coupling 23238–1 is required to run air–feed applicators.

End–feed and side–feed miniature applicators are easily installed and removed without repositioning the

applicator mounting plate on the machine.

2.1. Functional Description

These machines provide the force required to crimp terminals in the applicator. A terminal is attached to the

wire by placing the wire in the crimp area and pressing the foot switch. The machine consists of four functional

areas:

1. The

motor group includes a dc motor which drives a crankshaft. The motor is activated each cycle

and rotates the crankshaft one full revolution. A motor access cover, located on the end of the motor,

covers a hex key which allows the motor to be cycled manually. See Figure 4.

2. The

crankshaft–ram group covers the motor rotational force to the up–and–down action of the ram

for driving the applicator during the crimping cycle.

3. The

base plate provides the mounting surface on which the applicator is installed. The quick–release

latching feature on Machines –2, –3, –4, –6, and –7 permits fast, easy installation and removal of the

applicator. Note that Machines –1 and –5 do not include the quick–release latching feature.

See Figure 5.

4. The

crimp height adjustment group uses an eccentric located in the ram linkage, along with

detented stops in the mechanism to adjust the crimp height. See Figure 5. Indexing the mechanism in

either direction will change the crimp height in increments of approximately 0.013 mm [.0005 in.] per

step.

NOTE

i