9

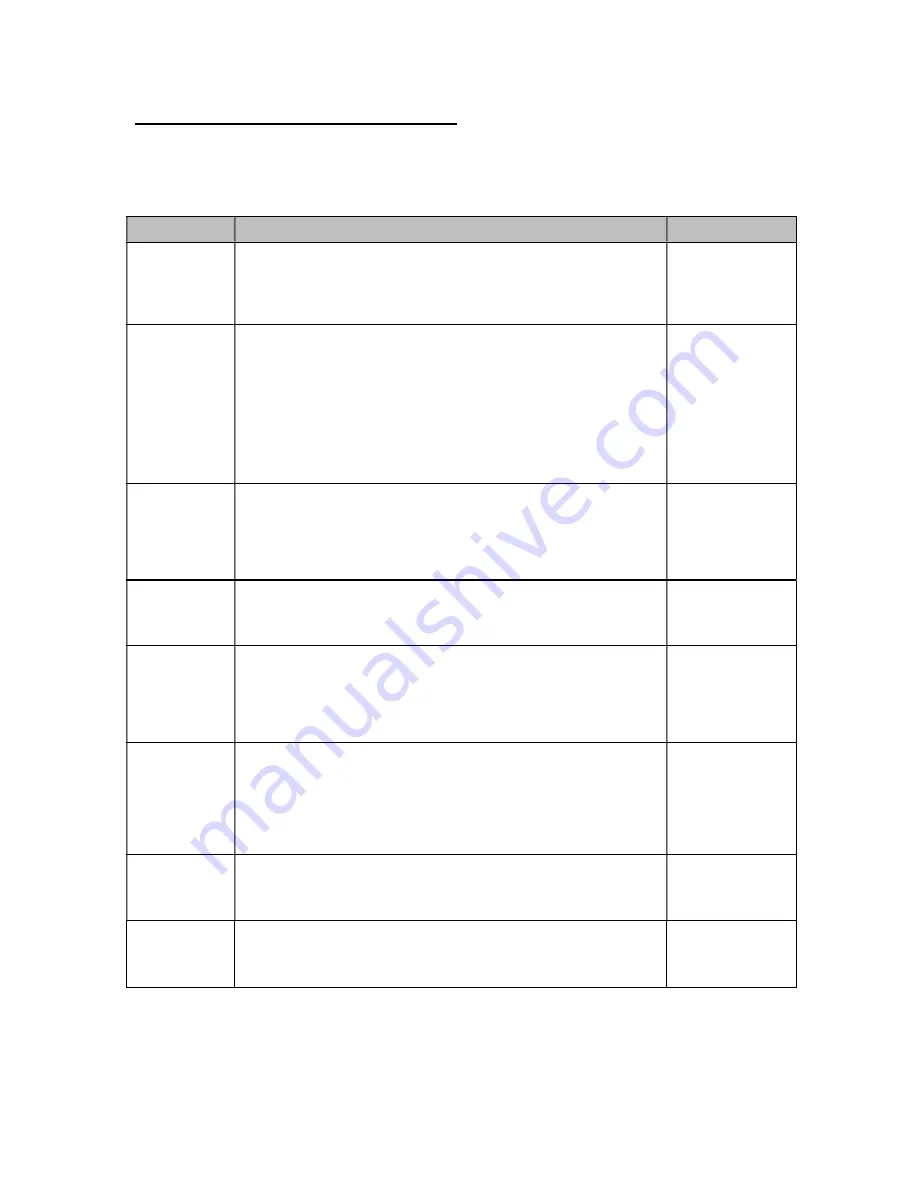

User (“A”) and COM (“C”) Menu Descriptions

This section provides more detailed descriptions of the selections found in the User Menu Chart.

Factory-set defaults are shown in

bold

with a checkmark;

(√)

.

CODE/NAME

DESCRIPTION

SELECTION LIST

A1/C1

Baud Rate

Selects the baud rate for data transmission through the serial port.

600, 1200, 2400,

4800,

9600

,

19200, 38400,

57600, 115200

A2/C2

Data Bits,

Parity and

Stop Bits

Selects the number of data bits and parity of serial transmission.

"8_n_1" = 8 data bits with no parity bit and one stop bit

"8_n_2" = 8 data bits with no parity bit and two stop bits

"7_n_1" = 7 data bits with no parity bit and one stop bit

"7_n_2" = 7 data bits with no parity bit and two stop bits

"7_E_1" = 7 data bits with even parity bit and one stop bit

"7_E_2" = 7 data bits with even parity bit and two stop bits

"7_o_1" = 7 data bits with odd parity bit and one stop bit

"7_o_2" = 7 data bits with odd parity bit and two stop bits

8_n_1

8_n_2

7_n_1

7_n_2

7_E_1

7_E_2

7_o_1

7_o_2

A3/C3

Serial Port

Mode

Selects the mode of the serial port: Refer to Appendix B for more

information.

"0" = Demand Full Duplex

"1" = Continuous Full Duplex

“2” = Auto Print

0

1

2

A4

MP-20 Print

Header

Tells MP-20 printer to print the header information. Valid only when

A6

is set to “2” or “4”.

"0" = Do NOT Print Header "1" = Print Header

0

1

A5

Units Key

Selects function of the Units key.

NOTE

: The UNITS key will not function if ounces or grams are se-

lected for F8.

"no" = Disabled

"YES" = Enabled

no

YES

A6/C6

Output String

Selects fixed output string for serial port. Refer to Appendix B for de-

tails.

"0" = String Format 1 (Condec Demand)

"1" = String Format 2 (Condec Continuous)

"2" = Text Print Ticket

“3” = Text Print Ticket with MP-20 Auto Label Feed

0

(A6)

1

2

(C6)

3

A7

ID Number

Selects the ID number mode.

"no" = Disabled

"YES" = Enabled

no

YES

A8

Set ID Number

Allows you to key-in the ID number. Pressing the ZERO/OFF key to

scroll down one level begins the sequence.

Key-in

0 to 999999

123456