9

General Information

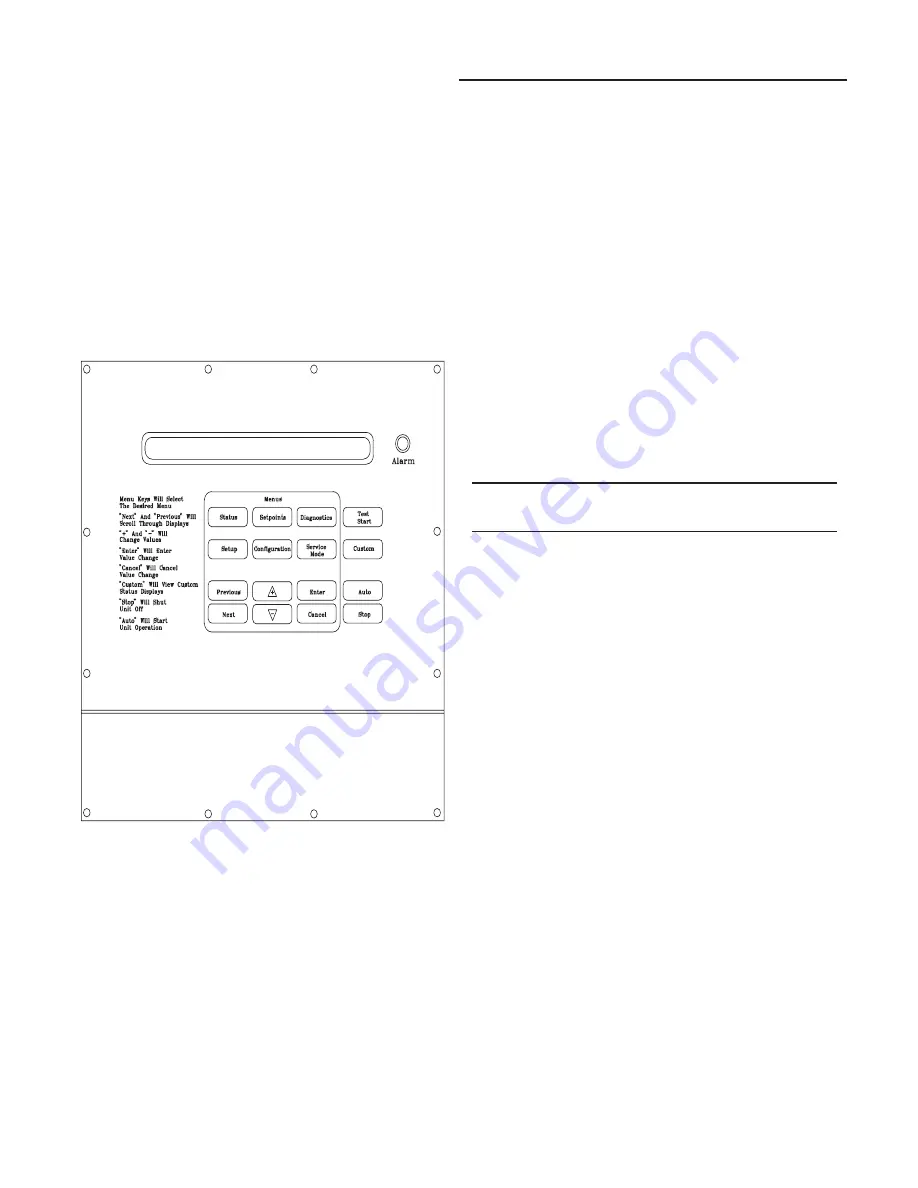

Menu Keys

The six keys illustrated in Figure 2 in the MENU area (STA-

TUS, SETPOINTS, SETUP, CONFIGURATION, DIAGNOS-

TICS, and SERVICE MODE) are used to bring up the vari-

ous interactive menus where the user inputs and accesses

unit operating data. Pressing these keys will display the ini-

tial screen for the menu designated by the key’s name. The

following information describes the keys and their functions

when viewing the various menus.

If no key is pressed for 30 minutes while the LCD is display-

ing a menu screen, it will revert back to the unit operating

status screen.

Figure 2

Human Interface Keypad

STATUS Key

Pressing the STATUS key causes the LCD to display the

operating status screen; i.e. "On", "Unit Stop", "External

Stop", "Emergency Stop", "Service Mode". Pressing the

NEXT key allows the operator to scroll through the screens

which provide information such as air and refrigerant tem-

peratures, pump operation, compressor operation, as well

as active cooling and compressor lockout setpoints. Press-

ing the STATUS key while viewing any of the data screens

will cause the LCD to go back to the operating status

screen.

SETPOINTS Key

Pressing the SETPOINTS key will cause the LCD screen to

display the first of the setpoint screens where the operator

will designate default temperature setpoints and setpoint

source information. While scrolling through the setpoint

screens, pressing this key again will cause the LCD to dis-

play the first setpoint screen.

DIAGNOSTICS Key

Pressing the DIAGNOSTICS key at any time will allow the

operator to view any unit function failures. The LCD screen

will display one of the diagnostic screens (depending on

which diagnostic, if any, is present). If no key is pressed for

30 minutes while the screen is displaying diagnostic infor-

mation, it will revert back to the operating status display.

CONFIGURATION Key

Pressing the CONFIGURATION key will cause the LCD

screen to display the first of the configuration screens

where the operator will designate unit configuration data

such as unit type, capacity, installed options, etc...

This information was programmed at the factory. Pressing

the configuration key at any level in the configuration menu

will display the first configuration screen.

Note: This key should be used if the unit's

configuration data is lost or new options are added

in the field, and to view current configuration.

SETUP Key

Pressing the SETUP key will cause the LCD screen to dis-

play screens where the operator will designate various op-

erating parameters such as temperature ranges, limits, per-

centages, etc. for the control of the unit’s various operating

modes. Pressing the SETUP key at any level in the SETUP

menu will display the first SETUP screen.

SERVICE MODE Key

Pressing the SERVICE MODE key causes the LCD to dis-

play the first of the service test mode screens showing vari-

ous unit components which may be turned on or off for the

particular test being performed. Once the status of these

components is designated, the LCD will display screens

that allow the operator to designate the TEST START time

delay for each test.

Data Manipulation Keys

The six data manipulation keys illustrated inFigure 2, (EN-

TER, CANCEL, + (Plus), - (Minus), PREVIOUS, and NEXT

are used to modify the data within the screens (change val-

ues, move the cursor, confirm choices, etc...)

ENTER Key

This key will confirm the new values that were designated

by pressing the + (Plus) or - (Minus) keys at all edit points.

When viewing status and diagnostics screens, it has no

function.

CANCEL Key

After changing data, at an editable screen, but before con-

firming it with the ENTER key, pressing the CANCEL key

will return the data to its previous value. This key shall also

function to clear active diagnostics.

Summary of Contents for IntelliPak CGAF Series

Page 68: ...68...