Testing

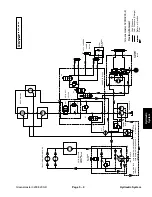

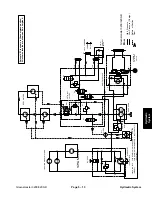

The most effective method for isolating problems in the

hydraulic system is by using hydraulic test equipment

such as pressure gauges and flow meters in the circuits

during various operational checks. (See the Special

Tools section in this Chapter.)

Before Performing Hydraulic Tests

IMPORTANT: All obvious areas such as oil supply,

filter, binding linkage, loose fasteners, or improper

adjustments must be checked before assuming that

a hydraulic component is the source of the problem

being experienced.

Precautions for Hydraulic Testing

CAUTION

Failure to use gauges with recommended

cedures could result in damage to the

gauge and possible personal injury from

leaking hot oil.

All testing should be performed by 2

people. One person should be in the seat

to operate the machine, and the other

should read and record test results.

CAUTION

Operate all hydraulic controls to relieve sys-

tem pressure and avoid injury from pressur-

ized hydraulic oil. Controls must be oper-

ated with the ignition switch in RUN and the

when pressure has been relieved. Remove

key from the ignition switch.

pressure (psi) rating as listed in test pro-

engine OFF. Return ignition switch to OFF

Before disconnecting or performing any

sure in the system must be relieved by

or

implements.

Keep body and hands away from pin hole

leaks or nozzles that eject hydraulic fluid

under high pressure. Do not use hands to

search for leaks; use paper or cardboard.

can have sufficient force to penetrate the

injected into the skin, it must be surgical-

ly removed within a few hours by a doctor

work on the hydraulic system, all pres-

stopping the engine and lowering

supporting the cutting units or other

Hydraulic fluid escaping under pressure

skin and cause serious injury. If fluid is

familiar with this type of injury. Gangrene

may result from such an injury.

WARNING

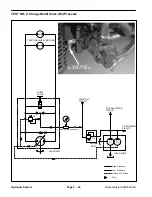

1. Thoroughly clean the machine before disconnect-

ing or disassembling any hydraulic components. Always

keep in mind the need for cleanliness when working on

hydraulic equipment. Contamination will cause exces-

sive wear of components.

2. Put caps or plugs on any hydraulic lines left open or

exposed during testing or removal of components.

3. The engine must be in good operating condition.

Use a tachometer when making a hydraulic test. Engine

speed can affect the accuracy of the tester readings.

4. The inlet and the outlet hoses must be properly con-

nected and not reversed (tester with pressure and flow

capabilities) to prevent damage to the hydraulic tester or

components.

Hydraulic System

Page 5 – 20

Greensmaster 3200/3200–D

Summary of Contents for 3200

Page 2: ...Greensmaster 3200 3200 D ...

Page 4: ...Greensmaster 3200 3200 D ...

Page 6: ...Greensmaster 3200 3200 D ...

Page 12: ...Safety Page 1 6 Greensmaster 3200 3200 D ...

Page 14: ...Equivalents and Conversions Product Records and Maintenance Page 2 2 Greensmaster 3200 3200 D ...

Page 17: ...Product Records and Maintenance Page 2 6 Greensmaster 3200 3200 D ...

Page 72: ...Perkins Diesel Engine Page 4 30 Greensmaster 3200 D ...

Page 113: ...Hydraulic System Greensmaster 3200 3200 D Page 5 41 Hydraulic System ...

Page 161: ...Hydraulic System Greensmaster 3200 3200 D Page 5 89 Hydraulic System ...

Page 173: ...Hydraulic System Greensmaster 3200 3200 D Page 5 101 Hydraulic System ...

Page 234: ...Wheels and Brakes Page 7 12 Greensmaster 3200 3200 D ...

Page 261: ...Cutting Units Greensmaster 3200 3200 D Page 8 27 Cutting Units ...

Page 273: ......

Page 274: ...Commercial Products FORM 96 900 SL E The Toro Company 1997 Printed in U S A ...