General Maintenance

4- 4

WFM700 Series Waveform Monitors Service Manual

Inspection — Exterior.

Inspect the outside of the instrument for damage, wear, and

missing parts, using Table 4--1 as a guide. Immediately repair defects that could

cause personal injury or lead to further damage to the instrument.

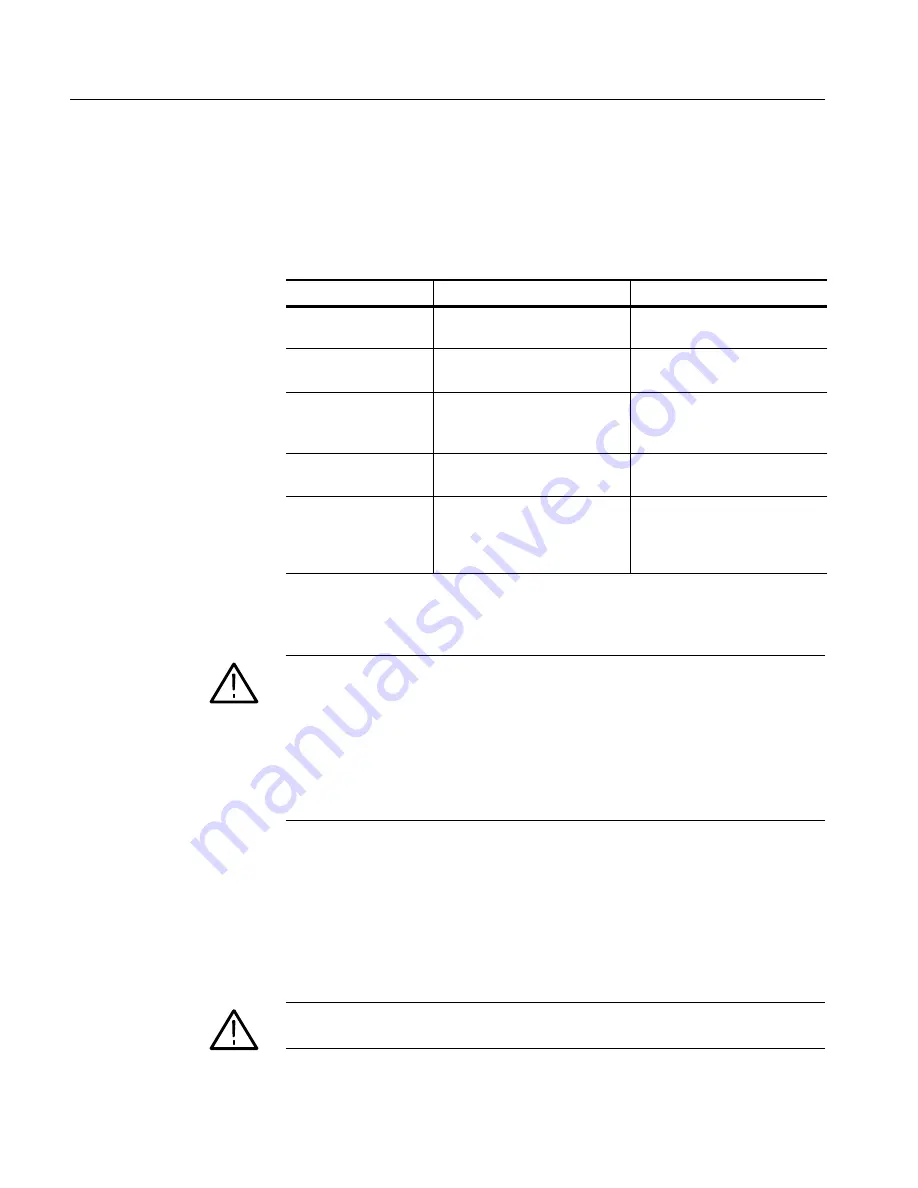

Table 4- 1: External inspection check list

Item

Inspect for

Repair action

Cabinet, front panel,

and cover

Cracks, scratches, deformations,

damaged hardware.

Repair or replace defective

module.

Front-panel knobs

Missing, damaged, or loose

knobs.

Repair or replace missing or

defective knobs.

Connectors

Broken shells, cracked insulation,

and deformed contacts. Dirt in

connectors.

Repair or replace defective

modules. Clear or wash out dirt.

Carrying handle, and

cabinet feet.

Correct operation.

Repair or replace defective

module.

Accessories

Missing items or parts of items,

bent pins, broken or frayed

cables, and damaged connec-

tors.

Repair or replace damaged or

missing items, frayed cables, and

defective modules.

The flat panel display must be treated with care during cleaning.

CAUTION.

Improper cleaning agents or methods can damage the flat panel

display.

Avoid using abrasive cleaners or commercial glass cleaners to clean the display

surface.

Avoid spraying liquids directly on the display surface.

Avoid scrubbing the display with excessive force.

Clean the flat panel display surface by gently rubbing the display with a

clean-room wipe (such as Wypall Medium Duty Wipes, #05701, available from

Kimberly-Clark Corporation).

If the display is very dirty, moisten the wipe with distilled water or a 75%

isopropyl alcohol solution and gently rub the display surface. Avoid using excess

force or you may damage the plastic display surface.

CAUTION.

To prevent getting moisture inside the instrument during external

cleaning, use only enough liquid to dampen the cloth or applicator.

Flat Panel Display

Cleaning

Summary of Contents for WFM700 Series

Page 4: ......

Page 10: ...Table of Contents vi WFM700 Series Waveform Monitors Service Manual...

Page 14: ...Service Safety Summary x WFM700 Series Waveform Monitors Service Manual...

Page 19: ...Theory of Operation...

Page 20: ......

Page 30: ...Theory of Operation 1 10 WFM700 Series Waveform Monitors Service Manual...

Page 31: ...Performance Verification...

Page 32: ......

Page 88: ...Performance Verification 2 56 WFM700 Series Waveform Monitors Service Manual...

Page 94: ...WFM700 WFM7M Input Module Test Record 2 62 WFM700 Series Waveform Monitors Service Manual...

Page 102: ...WFM700 WFM7HD Input Module Test Record 2 70 WFM700 Series Waveform Monitors Service Manual...

Page 107: ...Adjustment Procedures...

Page 108: ......

Page 132: ...Adjustments 3 24 WFM700 Series Waveform Monitors Service Manual...

Page 133: ...Maintenance...

Page 134: ......

Page 160: ...Removal and Installation Procedures 4 26 WFM700 Series Waveform Monitors Service Manual...

Page 176: ...Repackaging Instructions 4 42 WFM700 Series Waveform Monitors Service Manual...

Page 177: ...Replaceable Parts...

Page 178: ......

Page 194: ...Replaceable Parts 5 16 WFM700 Series Waveform Monitors Service Manual...