Reference

DG2040 Data Generator

3Ć57

Make Sequence Menu

A sequence is a function to output blocked pattern data in a predetermined order

as specified in a sequence table. In the sequence table, repeat count, trigger wait,

event jump, and calling subsequences are used, as well as placing the blocked

patterns in a sequential order.

H

The blocked patterns are output in the line-numbered order defined in the

sequence table.

H

A patterned data or subsequence can be defined in each line in the sequence

table.

H

A line can be repeated on output from 1 to 65536 times or continuously.

H

A line can wait trigger event for output.

H

A line can be jumped to a specified line by the trigger of event signal.

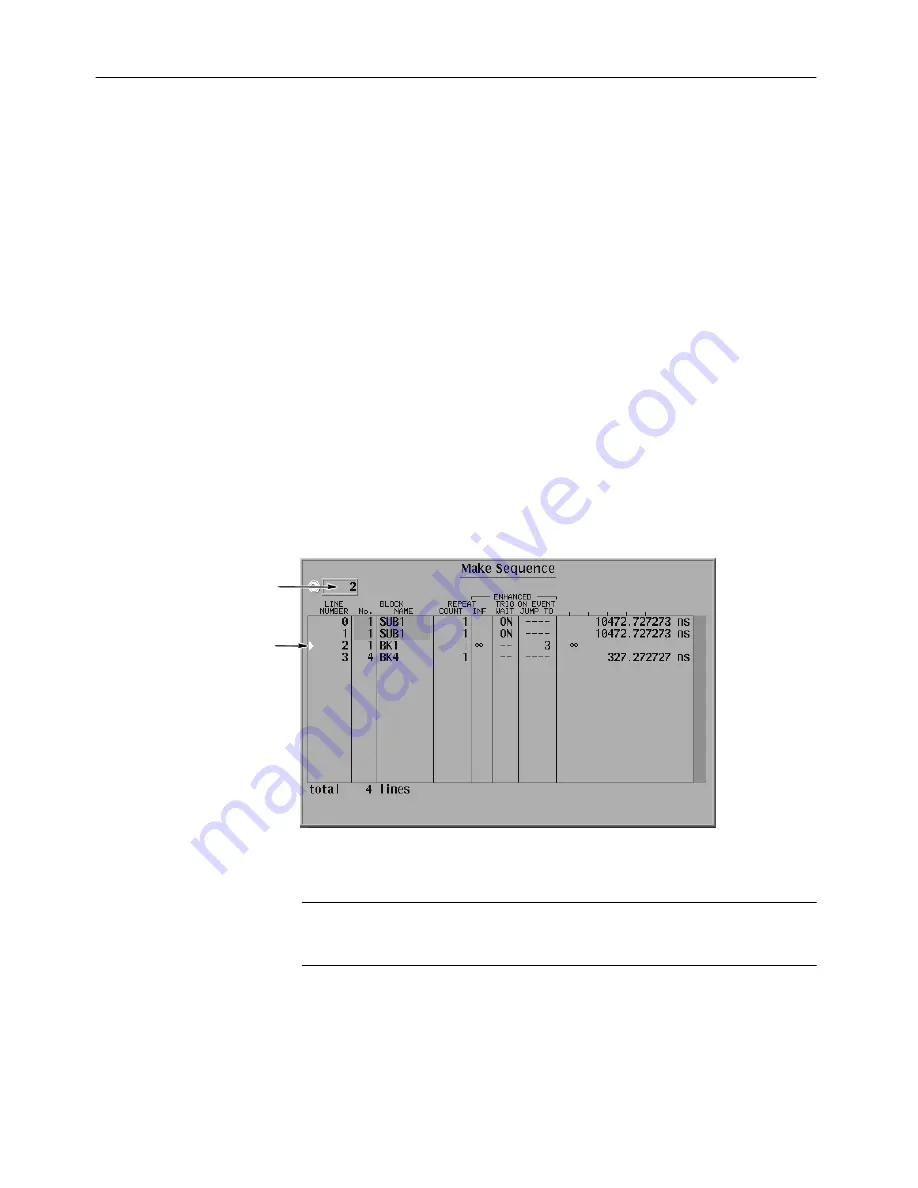

Figure 3-51 shows an example of a sequence. In this example, two subsequences

SUB1 waiting trigger event, a blocked pattern data BK1 to be infinitely repeated

and jumped to the line 3 on event signal, and blocked pattern data BK4 are

defined.

Line Pointer

Line number of

the current line

pointer position

Figure 3Ć51: Make Sequence menu and a sequence example

NOTE

. Enhanced columns in Figure 3-51 does not become effective unless the

run mode is not set to Enhanced. For enhanced mode, refer to Run Mode Menu

on page 3-74.

Summary of Contents for DG2040

Page 1: ...User Manual DG2040 Data Generator 071 0257 04 This document supports firmware version 1 00...

Page 4: ......

Page 18: ...Preface xiv DG2040 Data Generator...

Page 19: ...Getting Started...

Page 20: ......

Page 32: ...Getting Started 1 12 DG2040 Data Generator...

Page 33: ...Operating Basics...

Page 34: ......

Page 87: ...Reference...

Page 88: ......

Page 152: ...Reference 3 64 DG2040 Data Generator...

Page 186: ...Reference 3 98 DG2040 Data Generator...

Page 187: ...Appendices...

Page 188: ......

Page 200: ...Appendix A Specifications A 12 DG2040 Data Generator...

Page 248: ...Appendix B Performance Verification B 48 DG2040 Data Generator...

Page 258: ...Appendix C Miscellaneous C 10 DG2040 Data Generator...

Page 259: ...Index...

Page 260: ......

Page 265: ......

Page 266: ......