Engine

25/87

Z001138-1_2013-02-01

22. In case of a correct index value of engine

timing, remove locking pin on crankshaft

and tighten the hexagon nut of the

camshaft sprocket SW 30 with

240 Nm

by

holding up with special tool No. 2300711/0.

23.

ATTENTION:

The following torques are to

be checked again.

1. Torque on hexagon nut of camshaft

sprocket (SW 30)

□

240 +/- 12 Nm

2. Allen head screw (SW 8) of timing belt

tensioner at

□

45 +/- 4 Nm

3. 3 x TORX screws on vibration damper with

□

135 +/- 7 Nm

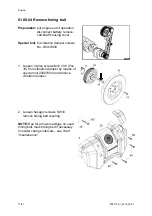

24. Remove adjustment tool from eccentric

shaft.

Remove camshaft sprocket

25. Loosen hexagon nut of camshaft sprocket

SW 30) by holding up with special tool No.

2300711/0 and turn nut by approx. ¼

rotation.

26. Mount extractor (ill.27/pos.1) camshaft

sprocket VR00113/0 and screw in puller

screw

"LEFTHAND

THREAD"

by hand.

Pre-stress puller screw with approx.

100 +/-5 Nm.

NOTE:

Do not remove camshaft sprocket from

conical seat when screwing in the puller screw.

Summary of Contents for Marine Engine 2012 Series

Page 35: ...General 35 65 Z001138 1_2013 02 01 Trouble Indication ...

Page 36: ...General Preliminary Service Manual MARINE 2012 Z001138 1_2013 02 01 36 65 ...

Page 51: ...General 51 65 Z001138 1_2013 02 01 G Notes on safety ...

Page 69: ...Engine Z001138 1_2013 02 01 4 87 Kapitel MOUNT BRACKET COVER T BELT GASKET SET ...

Page 154: ...Fuel System Z001138 1_2013 02 01 2 51 ...

Page 159: ...Fuel System 7 51 Z001138 1_2013 02 01 03 00 03 Unit injector ...

Page 190: ...Fuel System Z001138 1_2013 02 01 38 51 Schema Injection Timing Device ITD ...

Page 211: ...Cooling System 5 21 Z001138 1_2013 02 01 ...

Page 231: ...Electrical System Z001138 1_2013 02 01 4 47 ...

Page 235: ...Electrical System Z001138 1_2013 02 01 8 47 ...

Page 236: ...Electrical System 9 47 Z001138 1_2013 02 01 ...

Page 238: ...Electrical System 11 47 Z001138 1_2013 02 01 ...