Engine

Z001138-1_2013-02-01

24/87

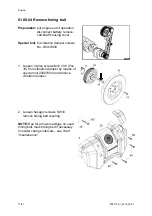

20. Put on tension gauge No. VR00515/0

between camshaft sprocket and tensioner,

as described under item 15, and read

measured value. Timing belt tension should

be

600 +/- 30 Nm

for a new timing belt.

NOTE:

In case of used belt adjust timing belt

tension should be

520 +/- 30 Nm.

NOTE:

If timing belt tension does not

correspond to desired value, loosen the

tensioner and repeat adjustment according to

instructions under item 15 to 20.

In this case, a re-positioning of the camshaft

sprocket may be required.

21. Turn crankshaft further 2 turns, and at

second turn fix crankshaft in TDC position

(cylinder 1; in TDC with locking pin in crank

shaft in TDC position (cylinder 1; in TDC).

See chapter 01.00.01. With crank shaft in

locked position, the plunger guide stroke of

the unit injector at first cylinder should

show the following value on the dial gauge:

Index value of engine timing

3.59 mm +/-

0,02 mm

(plunger guide stroke - unit

injector)

NOTE:

If the index value of engine timing

should not correspond to the specifically value,

follow the instructions as per item 25.

Summary of Contents for Marine Engine 2012 Series

Page 35: ...General 35 65 Z001138 1_2013 02 01 Trouble Indication ...

Page 36: ...General Preliminary Service Manual MARINE 2012 Z001138 1_2013 02 01 36 65 ...

Page 51: ...General 51 65 Z001138 1_2013 02 01 G Notes on safety ...

Page 69: ...Engine Z001138 1_2013 02 01 4 87 Kapitel MOUNT BRACKET COVER T BELT GASKET SET ...

Page 154: ...Fuel System Z001138 1_2013 02 01 2 51 ...

Page 159: ...Fuel System 7 51 Z001138 1_2013 02 01 03 00 03 Unit injector ...

Page 190: ...Fuel System Z001138 1_2013 02 01 38 51 Schema Injection Timing Device ITD ...

Page 211: ...Cooling System 5 21 Z001138 1_2013 02 01 ...

Page 231: ...Electrical System Z001138 1_2013 02 01 4 47 ...

Page 235: ...Electrical System Z001138 1_2013 02 01 8 47 ...

Page 236: ...Electrical System 9 47 Z001138 1_2013 02 01 ...

Page 238: ...Electrical System 11 47 Z001138 1_2013 02 01 ...