TROUBLESHOOTING

CHAPTER 5:

TROUBLESHOOTING

If the WORKSTATION 8 is required to be serviced on site (restaurant), it is

advisable that the service technician bring along a fully functional Workstation

in the event that the Workstation in question requires more than a simple

service. Swapping Workstations should be carried out in order to minimize

disruption to the site.

Troubleshooting on Workstations can be carried out using the Diagnostic

feature available in the Squirrel

One

POS software. Reference can be made to

the V1.3x Functions document or the V1.3x Managers Guide for detailed

information regarding the Diagnostic feature.

The Workstation 8 has thus far proven to be a very reliable product. However,

there is always a chance that you may experience some problems. Listed

below are some common problems and possible solutions.

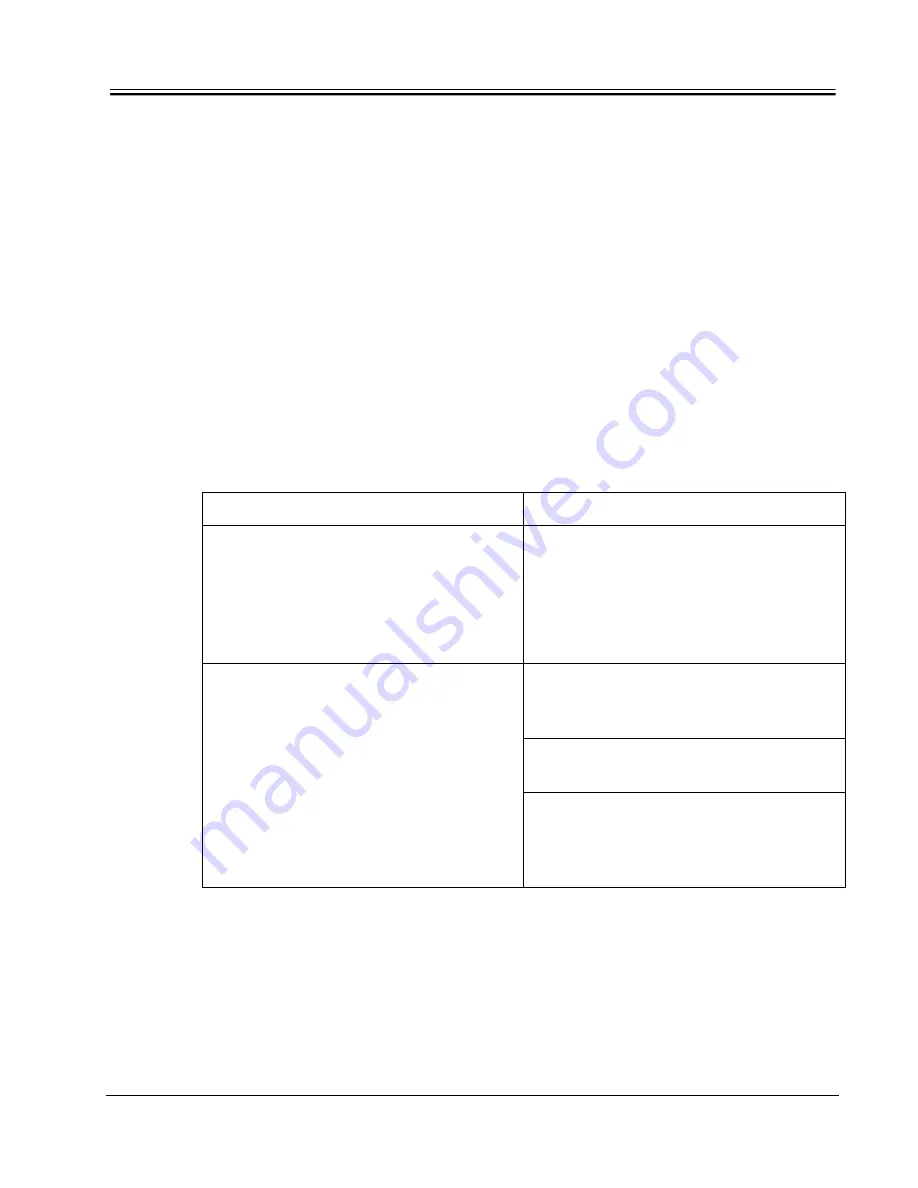

Problem Possible

Solutions

Workstation is ‘ON’ but the screen is

blank/dark.

Touch the screen or insert a badge

card to activate the backlight. If there

hasn’t been any activity on the

Workstation for approximately 2

minutes, the software turns off the

backlight to conserve power.

Check to make sure the touch-screen

sensor is connected properly to the

motherboard.

Connect another touch-screen sensor

to see if the problem is rectified.

No touch in some areas of the screen

and recalibration doesn’t fix the

problem.

Component failure in the touch-screen

sensor circuitry on the motherboard.

Send unit to Repair Depot for

servicing/replacement.

5-1 R1.0 Preliminary Release

3/24/05