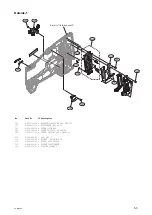

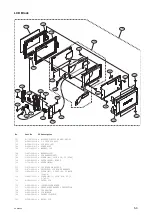

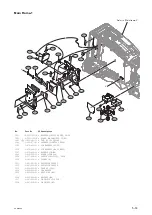

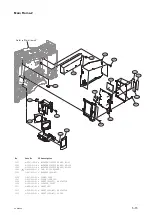

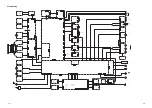

Handle Block-1

Refer to “Handle block-2”

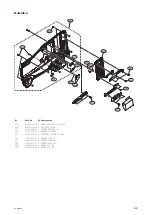

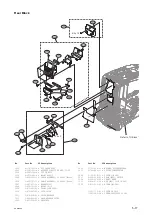

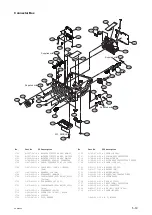

Refer to “Main frame-1”

1031

1001

1018

1016

1004

1010

1016

1025

1016

1017

1031

1023

1014

1030

1029

1027

1019

1013

1016

1006

1028

1005

1008

1021

1014

1014

1003

1020

1009

1016

1012

1016

1022

1024

1020

1011

1016

1002

1026

1031

1007

1015

B2.6 x 10

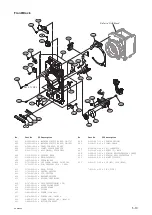

No.

Part No.

SP Description

1001

A-1106-989-A s COVER ASSY, SHOE

1002

A-2054-864-A s MOUNTED CIRCUIT BOARD, SW-1652

1003

A-2054-865-A s MOUNTED CIRCUIT BOARD, SW-1653

1004

A-2054-870-A s MOUNTED CIRCUIT BOARD, LED-529

1005

A-2057-509-A s MOUNTED CIRCUIT BOARD, CN-3723

1006

A-2059-048-A s MOUNTED CIRCUIT BOARD, GP-1019

1007

X-2541-837-4 s COVER ASSY, HANDLE (TOP)

1008

1-893-019-11 s FP-2231 FLEXIBLE PWB

1009

1-967-028-11 s HARNESS, SUB (LIGHT)

1010

1-967-783-11 s HARNESS (COAXIAL CABLE)

1011

1-970-443-11 s SUB HARNESS (GPS)

1012

3-337-402-01 o BAND, BINDING

1013

3-742-004-01 s RING, NYLON

1014

3-742-074-13 s SCREW (+B 3X8)

1015

3-805-990-01 s HANDLE TOP COVER LID

1016

3-855-938-01 s SCREW [+PSW 2x5]

1017

3-868-631-01 s CUSHION,DROP PROTECTION

1018

3-870-241-02 s COVER, LAMP

1019

3-870-243-02 s SEAL, LAMP COVER

No.

Part No.

SP Description

1020

3-965-077-02 s SCREW, SPECIAL (M2) [M2x2.4]

1021

4-000-665-01 s SEALING (B), HANDLE

1022

4-168-996-01 s CAP (LIGHT CONNECTOR)

1023

4-168-998-02 s COVER, TALLY

1024

4-264-451-01 s CAP (USB2)

1025

4-545-528-01 s SHEET (LED529), PROTECTION

1026

4-545-545-01 s BRACKET (GPS)

1027

4-549-673-01 s CUSHION (TAC)

1028

4-549-672-01 s CUSHION (HTC A)

1029

4-549-674-01 s CUSHION (H MID)

1030

4-549-937-01 s CUSHION (HTC B)

1031

4-654-273-02 s ACE (M2), LOCK [B 2x5]

7-621-775-50 s SCREW +B 2.6X10

PXW-X500

5-12

Summary of Contents for PXW-X500

Page 1: ...SOLID STATE MEMORY CAMCORDER PXW X500 SERVICE MANUAL 1st Edition ...

Page 4: ......

Page 8: ......

Page 10: ......

Page 54: ......

Page 87: ...3 Remove the tape AS Tape AS PXW X500 2 33 ...

Page 109: ...4 Install the removed parts by reversing the steps of removal PXW X500 2 55 ...

Page 158: ......

Page 183: ......

Page 184: ...PXW X500 SY PXW X500 CN J E 9 878 582 01 Sony Corporation Printed in Japan 2014 11 08 2014 ...