Operating manual - English

REKORD AY

Copyright Silca 2019

13

6

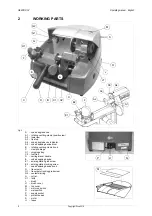

MACHINE REGULATION AND UTILIZATION

6.1

Checking and setting

The cutting tool on the REKORD AY is the part used to cut the key blanks and should be periodically

checked and replaced, if necessary.

Every time the cutting tool is changed, and during periodical operational tests, check calibration.

Fig. 12

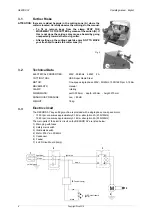

6.2

Gauging

The REKORD AY key-cutting machine requires two types of calibration: axis and depth.

Axial gauging

Axial gauging is regulation of the position of the cutting spaces (fig. 12 - A).

Axial gauging regulation

To regulate the axial gauging, proceed as follows:

ATTENTION: disconnect the machine from the mains.

1) set up the coded spacing device (fig. 13) by means of the knob (F) so that the indicator "5" is aligned

with position "2”.

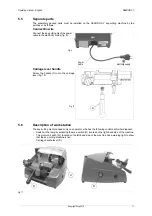

2) place the gauging calliper provided in the clamp (A1) (fig. 14), pushing towards the side of the tip stop

(A3), and secure by turning the knob (B).

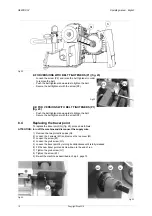

3) take the carriage towards the cutting tool and place the tracer point (G) all the way into the locating

groove (E3) (fig. 15, page 14).

4) check that the cutting tool enters clearly into the groove in the gauging calliper. If adjustment is

necessary, loosen screw (E2) and adjust axial gauging by means of the grub screw (E1) (fig. 13).

5) when gauging is complete, tighten the screw (E2) well.

Fig. 13

Fig. 14

A

B

view from the tip

E3

Q

F

E2

E1

Q1

gauging

caliper

groove

A3

B

A1