83/232

Building Technologies

Boiler sequence controller RMK770

CE1P3132en

HVAC Products

6 Boiler sequence management

23.04.2009

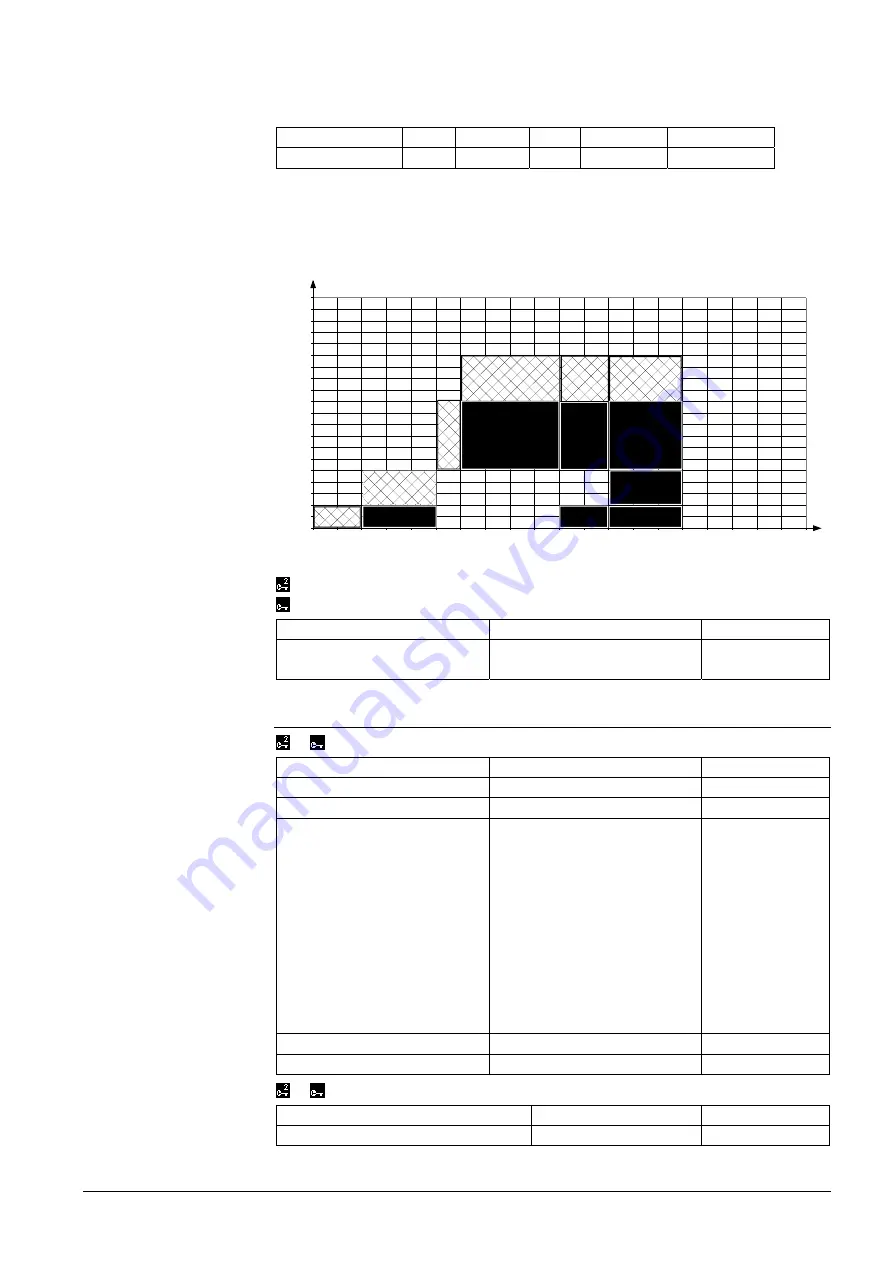

This approach can be chosen only if the output of the basic stage of boiler 2 exceeds

the rated capacity of boiler 1. If this strategy is chosen, a fixed boiler sequence makes

sense, thereby ensuring that the same boiler is always boiler no. 2.

Output stage

1 2

3 4

5

Boiler release

1.1 1.1+1.2 2.1 2.1+2.2 1.1+2.1+2.2

This switch-on order is called binary switching on. With the RMK770, binary switching

on is restricted to the first 2 boilers. The next boilers are switched sequentially. With

binary switching on, boiler 2 is always the controlling boiler.

Binary switching of boiler sequence with 2 boilers:

Output of boiler 1 = 100%, output of boiler 2 = 200%

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

3132D

03

Heat demand or load

Bo

il

e

r 1

Boil

e

r 2

Main menu > Commissioning > Settings > …

or

Main menu > Settings > Boiler sequence manager > Control parameters

Operating line

Range

Factory setting

Boiler sequence strategy

Sequentially / Binary-

sequentially

Sequentially

6.3.4

Boiler sequence operating mode

or

Main menu > Boiler sequence manager > Boiler sequence optg mode

Operating line

Range

Factory setting

Preselection

Off / Summer operation / Auto

Auto

State

On / Off

Cause Commissioning

Operating mode selector

Frost protection for consumer /

Flow/return frost protection /

Sustained mode

Overtemp protection / Overrun /

Protective boiler startup seq

Flue gas measuring mode

Manual control

No boiler sensor available /

No request / Request

Summer operation

Inactive / Active

Boil sequence selection manual Auto / 1…6

Auto

or

Main menu > Boiler sequence manager > Boiler sequence optg mode

Operating line

Range

Factory setting

Setp preselection manual

---- / 8…140 °C

---- °C

Example