6 Troubleshooting

Issue 04/02

MICROMASTER 410 Operating Instructions

60

6SE6400-5EA00-0BP0

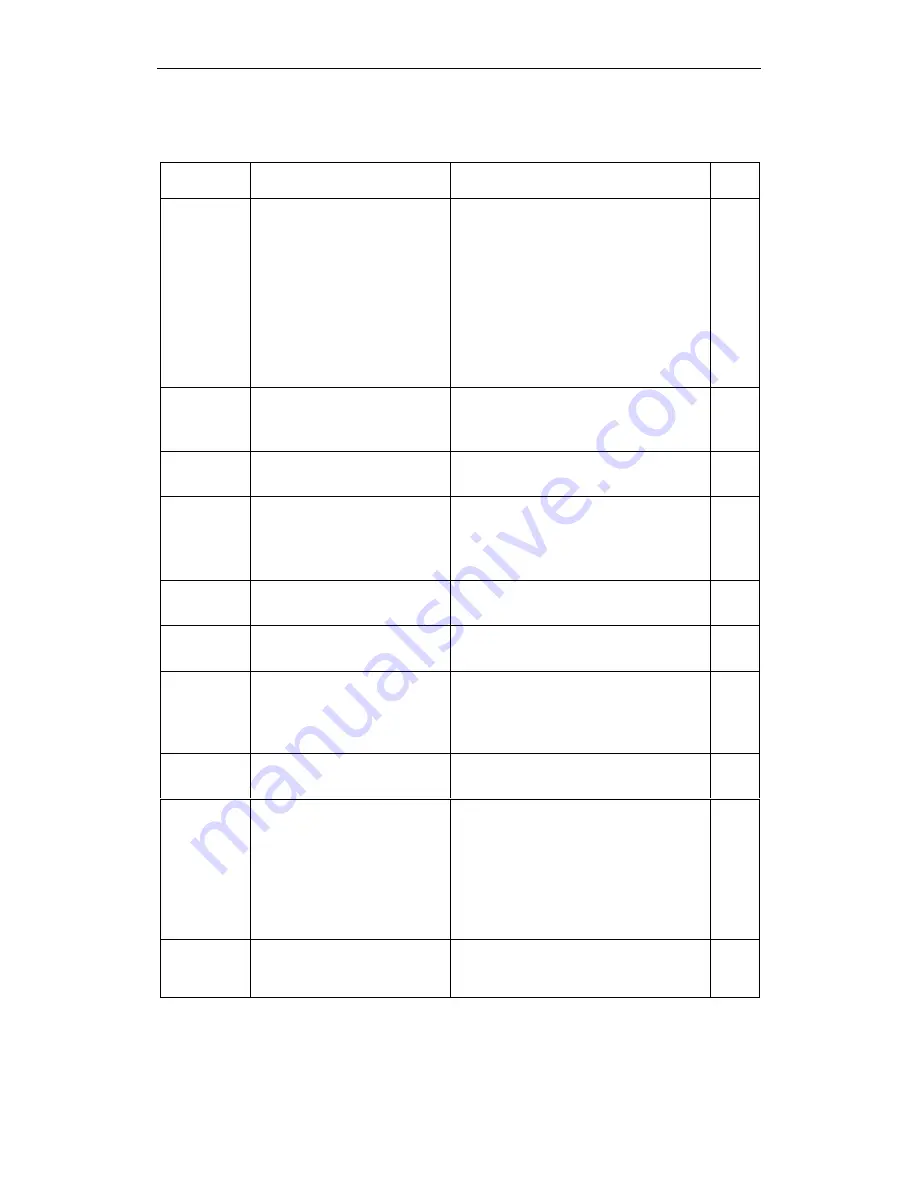

6.4 Alarms

Alarm

Possible Causes

Diagnose & Remedy

Reac-

tion

A0501

Current Limit

Ø

Motor power does not

correspond to the inverter power

Ø

Motor leads are too long

Ø

Earth

faults

Check the following:

1.

Motor power (P0307) must correspond to

inverter power (r0206).

2. Cable length limits must not be exceeded.

3. Motor cable and motor must have no short-

circuits or earth faults

4.

Motor parameters must match the motor in

use

5. Motor must not be obstructed or overloaded

Ø

Increase

the

ramp-up-time.

Ø

Reduce the boost.

--

A0502

Overvoltage

limit

Ø

Overvoltage limit is reached.

Ø

This warning can occur during

ramp down, if the dc-link con-

troller is disabled (P1240 = 0).

If this warning is displayed permanently, check

drive input voltage .

--

A0503

UnderVoltage

Limit

Main supply failed

Check main supply voltage (P0210).

--

A0504

Inverter Over

Temperature

Warning level of inverter heat-sink

temperature (P0614) is exceeded,

resulting in pulse frequency reduction

and/or output frequency reduction

(depending on parametrization in

(P0610)

Check the following:

1. Ambient temperature must lie within

specified limits

2. Load conditions and duty cycle must be

appropriate

--

A0505

Inverter I

2

t

Warning level exceeded, current will

be reduced if parameterized

(P0610 = 1)

Check that duty cycle lies within specified limits

--

A0506

Inverter duty

cycle

Difference between heatsink and

IGBT junction temperature exceeds

warning limits

Check that duty cycle and shock loads lie within

specified limits

--

A0511

Motor Over

Temperature

I

2

t

Ø

Motor

overloaded.

Ø

Load duty cycle too high.

Check the following:

1. P0611

(motor

I

2

t time constant) should be

set to appropriate value

2. P0614

(Motor

I

2

t overload warning level)

should be set to suitable level

--

A0600

RTOS Overrun

Warning

Software problem

Contact Service Department

--

A0910

Vdc-max

controller de-

activated

Ø

Vdc max controller has been de-

activated

Ø

Occurs if main supply voltage is

permanently too high.

Ø

Occurs if motor is driven by an

active load, causing motor to go

into regenerative mode.

Ø

Occurs at very high load inertias,

when ramping down.

Check the following:

1. Input voltage must lie within range.

2.

Load must be matched.

3. In certain cases apply braking resistor.

--

A0911

Vdc-max

controller

active

Vdc max controller is active; so ramp-

down times will be increased

automatically to keep DC-link voltage

(r0026) within limits

Check the inverter input voltage (P0210)

--

Summary of Contents for micromaster 410

Page 1: ......

Page 5: ......

Page 10: ...Safety Instructions Issue 04 02 MICROMASTER 410 Operating Instructions 10 6SE6400 5EA00 0BP0 ...

Page 14: ...Table of Contents Issue 04 02 MICROMASTER 410 Operating Instructions 14 6SE6400 5EA00 0BP0 ...

Page 44: ...3 Commissioning Issue 04 02 MICROMASTER 410 Operating Instructions 44 6SE6400 5EA00 0BP0 ...

Page 56: ...5 System Parameters Issue 04 02 MICROMASTER 410 Operating Instructions 56 6SE6400 5EA00 0BP0 ...

Page 62: ...6 Troubleshooting Issue 04 02 MICROMASTER 410 Operating Instructions 62 6SE6400 5EA00 0BP0 ...

Page 68: ...8 Options Issue 04 02 MICROMASTER 410 Operating Instructions 68 6SE6400 5EA00 0BP0 ...

Page 74: ......

Page 80: ...Index Issue 04 02 MICROMASTER 410 Operating Instructions 80 6SE6400 5EA00 0BP0 ...

Page 82: ...MICROMASTER 410 Operating Instructions 82 6SE6400 5EA00 0BP0 ...

Page 84: ......