mounting a rigid base (footed) motor vertically is the responsibility of

the installer.

VERTICAL SHAFT DOWN:

Most standard horizontal motors thru

449 Fr. (excluding brake motors) can be mounted in a vertical shaft

down orientation. For vertical brake motors see section 3.3.6.2.

VERTICAL SHAFT UP:

WARNING:

HAZARDOUS LOCATIONS VERTICAL

MOUNT:

Hazardous locations motors must

NOT

be mounted

vertically shaft up without approval by the motor manufacturer.

Without proper retaining provisions the rotor may move axially and

contact components, creating a spark hazard.

Belted or Radial Load when mounted vertically

: The

following frame sizes / constructions with applied (axial) down

loads within the limit stated are acceptable when mounted vertical

shaft up.

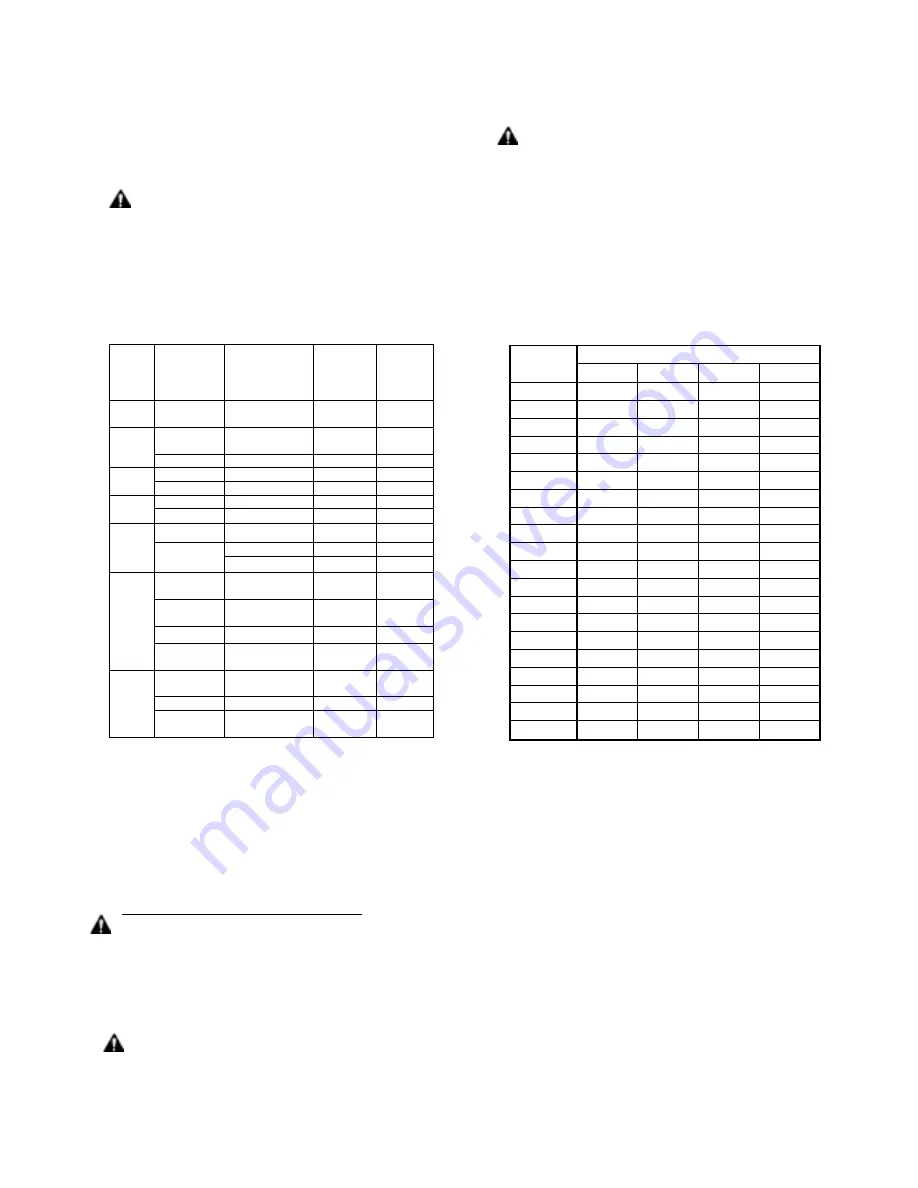

Table 3-1 Belted or Radial Load Applications (All speeds)

Frame

Size

Enclosure

Construction

Shaft Up

OK

Max

Applied

Down

Load

3

56

TEFC &

ODP

Steel

Yes

25 lbs

TEFC

Steel & Cast

Iron

Yes

25 lbs

140

ODP

Steel

Yes

25 lbs

TEFC

All

Yes

35 lbs

180

ODP

Steel

Yes

35 lbs

TEFC

All

Yes

40 lbs

210

ODP

Steel

Yes

40 lbs

TEFC

All

Yes

40 lbs

Steel

Yes

40 lbs

250

ODP

Cast Iron

No

2

N/A

320 TTFC

models

Cast Iron

Eng

1

N/A

All Other

TEFC

Cast Iron &

Aluminum

Yes

30 lbs

ODP

Cast Iron

No

2

N/A

280-320

TEFC &

ODP

Steel

Build Up

Only

4

N/A

TEFC

Cast Iron

Build Up

Only

4

N/A

ODP

Cast Iron

No

2

N/A

360 &

Up

TEFC &

ODP

Steel

Build Up

Only

4

N/A

Notes:

1

For TEFC model numbers beginning with 324TTFC or 326TTFC

consult the motor manufacturer to determine if a build up motor

is required.

2 The max applied down load is any applied load external to the

motor, including such things as sheave weight, fan loads, axial

belt force, pump load, etc. If the application is direct drive with

no applied radial load, consult the motor manufacturer.

3 ”Build-up only”, refers to motors that are specifically ordered

and built for shaft up applications. It does not imply that all build-

up motors are suitable for shaft up applications.

3.3

APPLICATION ASSEMBLY TO MOTOR:

CAUTION:

EQUIPMENT DAMAGE:

Do not connect or couple motor to load until correct rotational direction

is established.

3.3.1

GENERAL: PROPER ALIGNMENT

of the motor and

driven equipment minimizes vibration levels, maximizes bearing life,

and extends the overall life of the machinery. Consult the drive or

equipment manufacturer for more information.

CAUTION:

BEARING FAILURE

During assembly do NOT force components onto the shaft. Striking

or hammering the component may result in bearing damage.

3.3.2

DIRECT COUPLING:

Use flexible couplings if possible.

For applications that apply radial, axial or moment loading on the

motor shaft see section 3.3.3.

CAUTION:

BEARING FAILURE

Unless approved by the motor manufacturer do

NOT

direct couple a

vertical shaft up or roller bearing motor. Direct coupling a vertical

shaft up motor or a motor with a roller bearing may result in bearing

damage.

3.3.3

DIRECT CONNECTED:

Radial loading for direct

connected equipment (gears, fans etc.) must be approved by the

motor manufacturer unless within the maximum overhung load limits

(Table 3-2). Combined loading (axial, radial and/or moments) must

be approved by motor manufacturer. For belted loads see section

3.3.4.

Table 3-2 Maximum Radial Load (lbf) @ Middle of the Shaft

Extension Length

Motor Rated RPM

Frame

Number

3600

1800

1200

900

143T

106

166

193

210

145T

109

170

199

218

182T

187

230

261

287

184T

193

237

273

301

213T

319

317

470

510

215T

327

320

480

533

254T

500

631

729

793

256T

510

631

736

820

284T

-

866

990

1100

286T

-

871

1005

1107

324T

-

950

1100

1215

326T

-

950

1113

1230

364T

-

1078

1365

1515

365T

-

1078

1380

1540

404T

-

1388

1590

1762

405T

-

1400

1610

1780

444T

-

1580

1795

2005

445T

-

1520

1795

1985

447T

-

1455

1765

1985

449T

-

1640

1885

2130

Values based on 26,280 hrs B-10 Life

For “End of Shaft” Load multiply value by 0.88

To convert from lbf to N multiply value by 4.4482.

3.3.4

BELTED:

The goal of any belted system is to efficiently transmit the required

torque while minimizing the loads on the bearings and shafts of the

motor and driven equipment. This can be accomplished by following

four basic guidelines:

1.

Use the largest practical sheave diameter.

2.

Use the fewest number of belts possible.

3.

Keep sheaves as close as possible to support bearings.

4.

Tension the belts to the lowest tension that will still transmit the

required torque without slipping. It is normal for V-belts to

squeal initially when line starting a motor

3.3.4.1

Sheave Diameter Guidelines:

In general, smaller sheaves produce greater shaft stress and shaft

deflection due to increased belt tension. See Table 3-3 for

recommended minimum sheave diameters. Using larger sheaves

increases the contact with belts which reduces the number of belts

required. It also increases the belt speed, resulting in higher system

efficiencies. When selecting sheaves, do not exceed the

manufacturer's recommended maximum belt speed, typically 6,500

feet per minute for cast iron sheaves. Determine belt speed by the

following formula:

Summary of Contents for BW 10

Page 26: ......

Page 27: ......

Page 28: ......

Page 30: ......

Page 32: ......

Page 63: ......

Page 65: ...Section 1 General Information ii Table of Contents MN400 ...

Page 79: ...3 6 Maintenance Troubleshooting MN400 ...

Page 80: ...Baldor District Offices Baldor District Offices Baldor District Offices ...

Page 82: ......

Page 84: ......

Page 85: ...Meadowbank mining Corp ACP 700R Technical Data Sheet Reference NC01 DOSING PUMP ...

Page 86: ......

Page 111: ......

Page 112: ......

Page 113: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 158: ...BIM 1010 2005 03 6 www nord com ...

Page 162: ...BIM 1010 2005 03 10 www nord com PARTS LIST ...

Page 163: ...BIM 1010 2005 03 11 www nord com NOTES ...

Page 180: ......

Page 181: ......

Page 186: ......