INTRODUCTION

b. Put waxed paper or similar film on the sur-

faces.

– Twist bolt when inserting it to improve thread

conformation.

NOTE:

NOT intended for engine stud repairs.

Repair of Small Holes/Fine Threads

Option 1:

Enlarge damaged hole, then follow

STANDARD THREAD REPAIR procedure.

Option 2:

Apply FORM-A-THREAD on the screw

and insert in damaged hole.

Permanent Stud Installation (light duty)

– Use a stud or thread on desired length.

– DO NOT apply release agent on stud.

– Do a STANDARD THREAD REPAIR.

– Allow to cure for 30 minutes.

– Assemble.

Gasket Compound

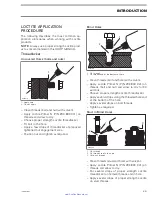

A00A3SA

2

1

1

3

1

1. Proper strength Loctite

2. Loctite Primer N (P/N 293 800 041) and Gasket Eliminator 518

(P/N 293 800 038) on both sides of gasket

3. Loctite Primer N only

– Remove old gasket and other contaminants

with Loctite Chisel remover (P/N 413 708 500).

Use a mechanical mean if necessary.

NOTE:

Avoid grinding.

– Clean both mating surfaces with solvent.

– Spray Loctite Primer N on both mating surfaces

and on both sides of gasket. Allow to dry 1 or

2 minutes.

– Apply GASKET ELIMINATOR 518 (P/N 293 800

038) on both sides of gasket, using a clean ap-

plicator.

– Place gasket on mating surfaces and assemble

immediately.

NOTE:

If the cover is bolted to blind holes (above),

apply proper strength Loctite in the hole and on

threads. Tighten.

If holes are sunken, apply proper strength Loctite

on bolt threads.

– Tighten as usual.

Mounting on Shaft

Mounting with a Press

A00A3UA

1

2

3

1. Bearing

2. Proper strength Loctite

3. Shaft

– Clean shaft external part and element internal

part.

– Apply a strip of proper strength Loctite on shaft

circumference at insert or engagement point.

NOTE:

Retaining compound is always forced out

when applied on shaft.

– DO NOT use anti-seize Loctite or any similar

product.

– No curing period is required.

Mounting in Tandem

1. Apply retaining compound on internal element

bore.

2. Continue to assemble as shown above.

smr2005-002

XV

www.SeaDooManuals.net