Sauter flexotron®800

ventilation

Functional description

P100012082

38

on and off times can be set, i.e. the minimum time the step has to be inactive or active

for a change to occur.

Binary

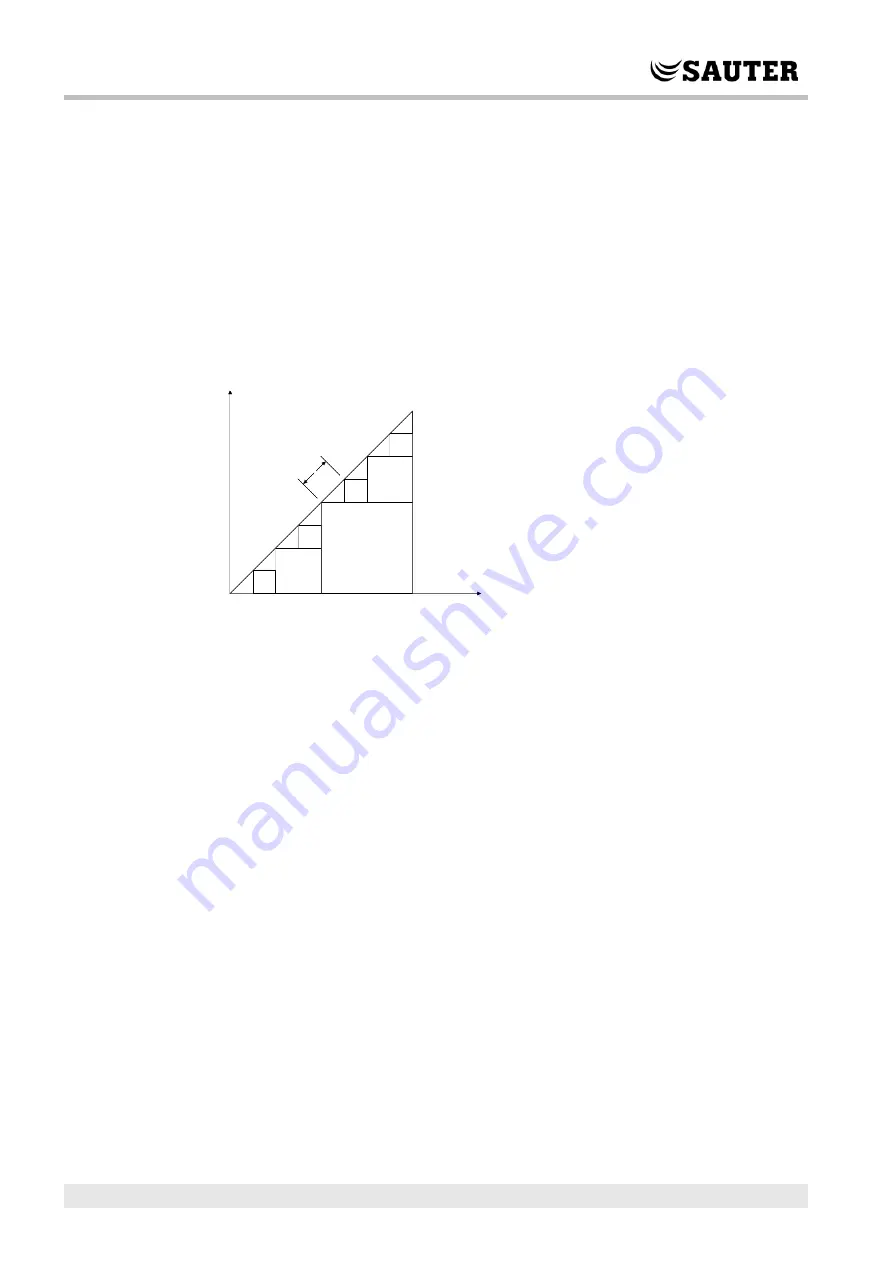

The heater power outputs should be binary weighted (1:2:4:8 for heating, 1:2:4 for

cooling). The number of loads to be controlled is set. Thereafter the program will

automatically calculate the individual activation levels. Switching differential and

minimum on/off times can be set. The number of heating steps will be: 2

no. of groups

-1. In

binary mode, the analogue output signal may be used to fill out between the steps. The

signal will g

o 0…100 % between the activation of each step. The load connected to the

analogue signal should have the same size as the smallest of the binary groups. In the

example below there are 4 heater groups (1:1:2:4) and the total number of heating

steps is eight.

Step controllers and Change-over

The digital output signals "Heating/cooling step 1", "Heating/cooling step 2" and

"Heating/cooling step 3" are used for step controllers during Change-over control (see

section 5.1.12). They have the same functions as other step controller outputs, but are

set to either heating or cooling depending on whether heating or cooling is required.

DX cooling with room or extract air control

If DX cooling is used in conjunction with room temperature control or extract air

temperature control, there are two configuration alternatives, DX cooling or DX cooling

with exchanger control.

DX cooling without exchanger control

When running cascade control, the supply air controller setpoint is normally controlled

by the room/extract air controller output signal.

When DX cooling is activated, the cooling controller setpoint is lowered to five degrees

(adjustable) below the setpoint given by the room/extract air controller. This prevents

the DX cooling from being activated/deactivated too often.

1

1

1

1

2

4

2

Y1 = 1