Operating Instructions Combics Indicators

109

Example

: Output weight value of +1255.7 g

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

G # * * * * + * * * 1 2 5 5 . 7 * g * * CR LF

Positions 1-6:

ID code, right-justifi ed with spaces

Position 7:

Plus +, or minus - or space

Position 8:

Space

Positions 9-16: Weight value with decimal point; leading zeros are output as

spaces (a comma can also be set instead of a decimal point,

menu item 7.17).

Position 17:

Space

Positions 18-20: Characters for unit of measure, space or

!

sign as a symbol

Position 21:

Carriage return

Position 22:

Line feed

h

If the weight value is output with 10-fold increased resolution, this value is not

permitted to be printed or saved in a weighing instrument operated in legal

metrology in the SBI mode. In this case, the unit symbol is not included with output.

Error message

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

S t a t * * * * * E r r * * # # * * * * CR LF

S t a t * * * * * E r r * # # # * * * * CR LF

*: Space

#:

Number (2 or 3 digit error number)

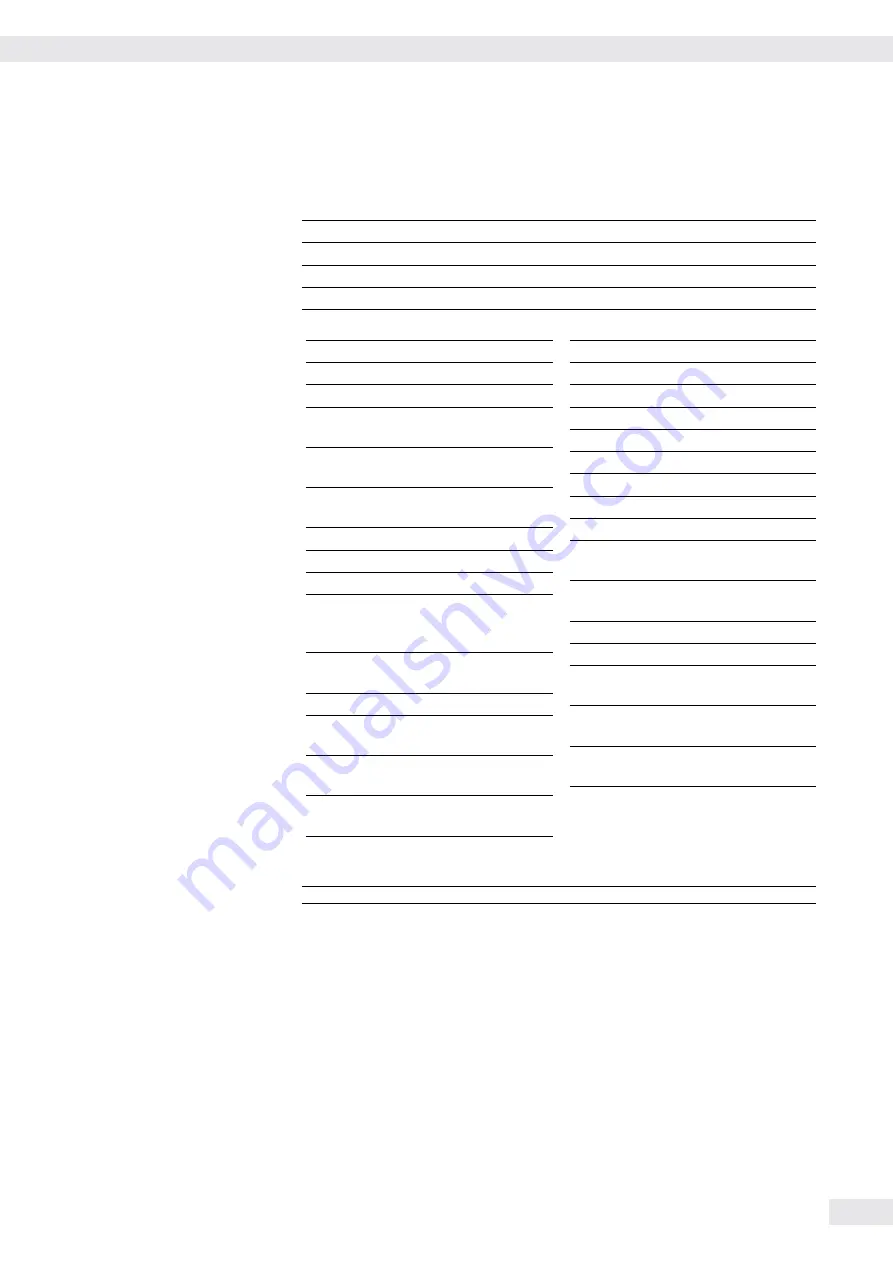

G#

Gross value

N

Net value

T

Application tare memory 1

T2

Application tare memory 2

Diff

Difference from calibration

value

Targ.

Exact adjustment weight

value

Nom.

Exact calibration weight

for SBI protocol output

nRef

Reference sample quantity

pRef

Percentage of reference

wRef

Reference piece weight

Qnt

Result from Counting (piece

count) and Neutral

Measurement applications

mDef

Target value for animal

weighing

x-Net

Animal weighing results

Setp

Target value for

checkweighing

Diff.W

Absolute difference (e.g., in

kg) in Checkweighing

Lim

Deviation in % in

Checkweighing

Max

Upper tolerance for checkw.

Min

Min. tolerance for checkw.

Stat

Status

Classx

Classifi cation

Limx

Class limit

D

Percentage (as loss)

Prc

Percentage (as residue)

Wxx%

Reference percentage weight

Cmpxxx

Component xxx

Cont.T

Contents of the tare memory

in Net-total Formulation

S-Comp

Total of initial weighings for

Net-total formulation

PT2

Preset tare

n

Transaction counter

*G

Sum of gross weights in

Totalizing

*N

Sum of net weights in

Totalizing

Ser.no

Serial number of the platform

or indicator

Data Interfaces

Summary of Contents for CAIS1

Page 127: ...Operating Instructions Combics Indicators 127 Declarations of Conformity...

Page 128: ...128 Operating Instructions Combics Indicators Declarations of Conformity...

Page 129: ...Operating Instructions Combics Indicators 129 Declarations of Conformity...

Page 130: ...130 Operating Instructions Combics Indicators Test Certificate...

Page 131: ...Operating Instructions Combics Indicators 131 Plates and Markings...

Page 132: ...132 Operating Instructions Combics Indicators Plates and Markings...

Page 133: ...Operating Instructions Combics Indicators 133 Plates and Markings...

Page 134: ...134 Operating Instructions Combics Indicators Plates and Markings...

Page 155: ...Operating Instructions Combics Indicators 155 Appendix Guide to verification...

Page 158: ...158 Operating Instructions Combics Indicators...

Page 159: ...Operating Instructions Combics Indicators 159...