5-52

MAINTENANCE

SY500H Excavator OMM

Increase the Track Tension

1. Prepare the machine for service. See “Maintenance

0004782

Figure 5-106

2. Clean all debris from the grease fitting access port

(1).

0004747

Figure 5-107

3. Using a grease gun, grease the fitting (2) to move the

idler out and tighten the track.

4. Slowly move the machine forward two machine

lengths.

5. Stop the machine.

6. Recheck the track tension. See “Check the Track

7. Repeat step 1 if the track tension is not within the

specified range.

Decrease the Track Tension

WARNING

Do not loosen the grease fitting! The grease fitting

is under extreme pressure and can exit the grease

valve quickly and forcefully, which could result in

death or serious injury. Do not stand directly in

front of the grease valve when loosening the

valve. Wear suitable personal protective

equipment (PPE) in the form of protective

clothing, gloves, safety glasses, and head

protection to protect against the sudden release

of pressurized grease.

1. Prepare the machine for service. See “Maintenance

0004782

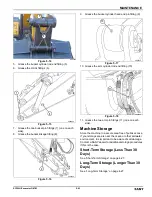

Figure 5-108

2. Make sure there is no gravel or mud between the

sprocket and the track shoe before decreasing track

tension.

Figure 5-109

1

2

1

0000812

2

Summary of Contents for SY500H

Page 2: ...Page Intentionally Blank ...

Page 14: ...5 10 SY500H Excavator OMM Page Intentionally Blank ...

Page 30: ...2 8 SAFETY SY500H Excavator OMM Page Intentionally Blank ...

Page 70: ...3 40 MACHINE CONTROLS SY500H Excavator OMM Page Intentionally Blank ...

Page 172: ...5 64 MAINTENANCE SY500H Excavator OMM Page Intentionally Blank ...

Page 180: ...6 8 SPECIFICATIONS SY500H Excavator OMM Page Intentionally Blank ...

Page 194: ...I 8 SY500H Excavator OMM Page Intentionally Blank ...

Page 195: ...Page Intentionally Blank ...