59

60

Usage of each feature

Usage of each fea

ture

Usa

ge of ea

ch feature

SYSTEM MENU

SYSTEM

Supplement

●If the operation does not return to normal after calibration,

contact Sanwa Service.

CALIBRATION

●Due to wearing and tearing of the internal mechanical elements

over the usage time, the neutral position and the operation angle

might become off.

In such case, you can correct the neutral positions of the steering

and the throttle and the operation angle.

1)Select [SYSTEM] with the multi-selector and determine

with the Enter operation.

2)Select [CALIBRATION] with the multi-selector and determine

with the Enter operation.

3)Select a channel to calibrate with the multi-selector and

determine with the Enter operation.

4)When selecting [STEERING], operate the Enter with the steering

wheel in neutral, then operate the steering wheel fully to left

and right.

5)When entering the range, [OK] is displayed. Operate following

the display.

6)When calibration is done, [Executed] is displayed.

7)If the throttle side also needs calibration, refer to the steering

to set.

*Unless necessary, do not set up calibration. If the setting is

not done properly, it may not operate normally.

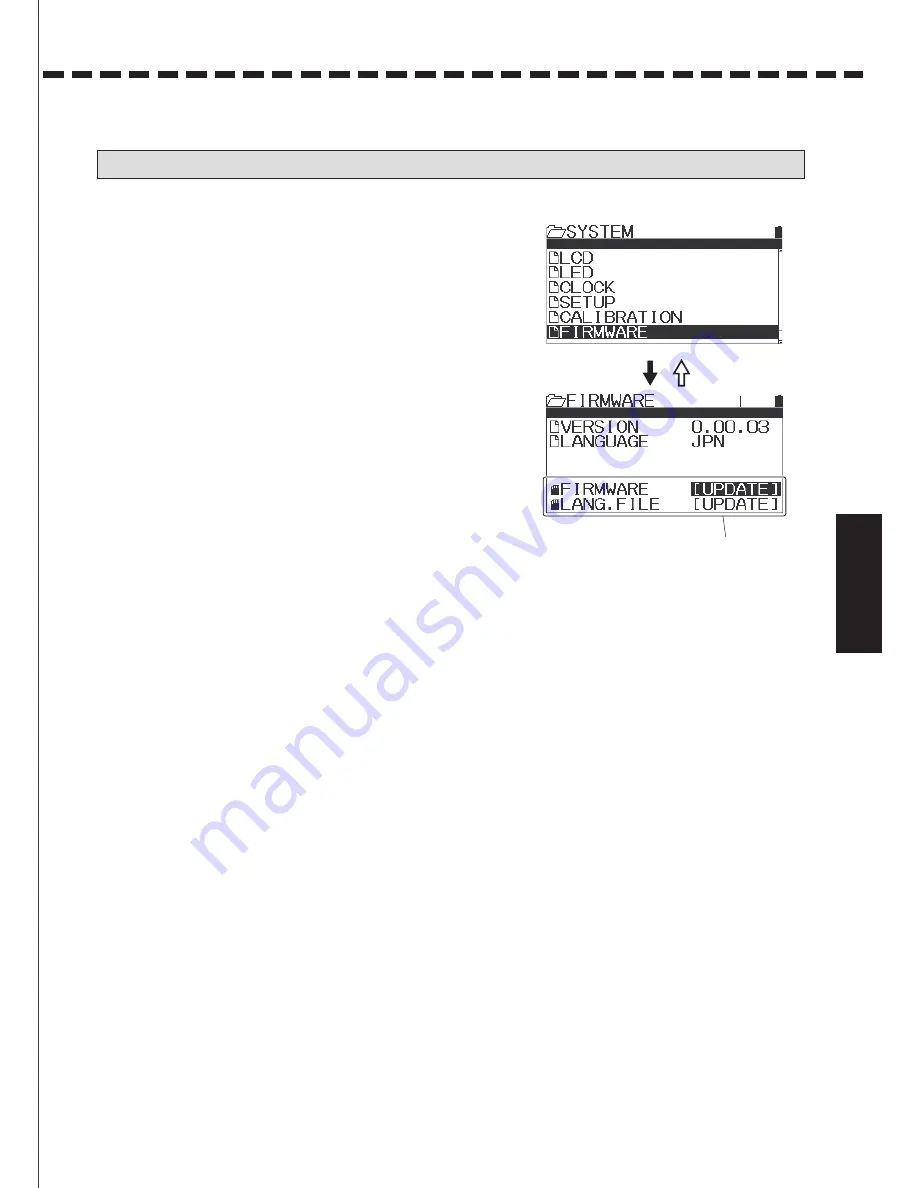

FIRMWARE

●You can check the firmware version installed on the main body unit

and the language file, and run updating.

1)Select [SYSTEM] with the multi-selector and determine with

the Enter operation.

2)Select [FIRMWARE] with the multi-selector and determine

with the Enter operation.

3)When updating the firmware and the language file, download

the data file onto the micro SD card to proceed.

ENTER

BACK

ENTER

BACK

ENTER

BACK

Select Yes, if it is OK.

⇒

Calibration complete

YES Selected.

Unless you insert

a micro SD card,

it will not be displayed.

ENTER

Summary of Contents for MT-44

Page 1: ... 90478 ...

Page 68: ......