S&C Instruction Sheet 766-510

19

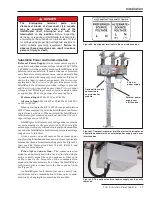

Figure 26. Interrupters open and tagged.

Figure 25. Opening interrupters manually with a hookstick

(shown in the Ready position).

Figure 27. Closing interrupters with a hookstick.

Operation

Local Operation

To enable local operation, on the

Operation

screen, set the

Remote Operation selection box to the

Disabled

setting.

See Figure 23 on page 18.

The IntelliRupter fault interrupter can now be operated

only by local commands via the Wi-Fi comunication link.

Select the OPEN or CLOSE operation button as appropri-

ate. The three interrupter OPEN/CLOSE indicators on

the underside of the IntelliRupter fault interrupter base

indicate the contact positions of the interrupters. See

Figure 24 on page 18. The red target with an “I” indicates

the interrupter is closed; the green target with an “O” indi-

cates the interrupter is open. The OPEN/CLOSE indicators

do not show the status of the hookstick-operated discon-

nect on disconnect style models. Set remote operation to

the

On

setting to allow remote commands to control the

IntelliRupter fault interrupter.

Manual Operation

The interrupters can be opened and closed manually using

the interrupter OPEN/CLOSE/READY lever.

Manual Lever Open

—Pull the OPEN lever down.

See Figure 25. The three interrupters will be physically

opened, and a mechanical block on each actuator prevents

the actuator from electrically closing its interrupter. The

open position can be “tagged” using conventional tagging

procedures. See Figure 26. Manually opening the interrupt-

ers does not require control power; it may be performed

during an outage. If control power is available, an elec-

tronic assist will open all closed poles.

Manual Lever Close

—The interrupters can only be

closed when control power is available. To close the inter-

rupters using a hookstick, first return the OPEN lever to

the

Ready

(up) position. Pull the CLOSE lever down

once

to effect the first closing profile or twice, without delay,

to effect the second closing profile.

The IntelliRupter

fault interrupter will use the specified closing-protection

profile to close the interrupters. See Figure 27. Closing

profiles initiated by the manual lever will be three-phase

commands and will attempt to close all open poles using

the associated closing profile protection elements.

For example, assume poles 1 and 3 are open and pole 2

is closed. A single pull on the CLOSE lever will initiate a

PulseClosing

®

Technology operation on pole 1, and if it

results in a successful close, a PulseClosing Technology

operation will be initiated on pole 3. If a fault is detected at

any time during the PulseClosing sequence, either single-

phase or three-phase tripping will result, in accordance

with the configuration for the active general profile.

Manual Lever Position

—Either the

Ready

tab or the

Lock

tab will always be visible. The IntelliRupter fault

interrupter will not respond to an

Open

or

Close

com-

mand, or perform any automatic operation when locked

open by the OPEN/CLOSE/READY lever (

Lock

tab is vis-

ible). The line crew should place the manual lever in the

Ready

position before leaving the site, unless the unit is

being purposely disabled.