26

Rotary Cylinder

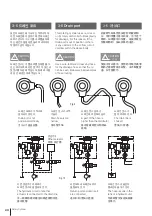

시운전시 뿐만 아니라,통상사용시에도

상기와 같은 형태의 실린더 작동이 안될

경우 아래의 조작을 시도해 보 십시오.

1. 주축이 회전하고 있는 경우에는

회전을 정지하여 주십시오.

2. 유압유니트부에 있는 척 설정압력

(실린더 설정압력)용 감압밸브의

압력조절 핸들을 돌려, 척 설정압력

을 약 0.5Mpa 높게, 실린더의 작동전

환 스위치를 수회 반복전환하여,

실린더의 작동을 확인하여 주십시오.

3. 그래도 작동이 안 되는 상태가

계속되는 경우에는 척의 설정압력을

높게 변경하면서 (약0.5Mpa씩), ⑵항

과 같이 조작을 반복하고, 실린더의

작동을 확인하여 주십시오. 그 경우

압력을 올리는 상한은 척 최대 사용

압력의 30%까지 해주십시오.

실린더가 작동한 후에는 원래의 척

의 설정압력으로 놓아 주십시오.

4. 척의 설정압력을 최대까지 올리고

상기 (3)항의 조작을 수회 실시해도

실린더의 조작이 안될 경우는, 척 설

정압력을 원래의 척 설정압력으로

놓은후 전원을 끄고, 실린더 표면의

온도가 실온과 거의 같게 될 때까지

냉각한후, 상기(2), (3)항의 조작을

반복하고, 실린더의 작동을 확인하

여 주십시오.

주) 에어 컨디셔너등에 의해 강제

적으로 공기를 실린더에 불어주

는 것은 보다 빠르게 실린더를

냉각시킬 수 있습니다.

5. 실린더 냉각 후에도 작동이 안될 때

는 척 쪽의 드로우 너트를 느슨하게

풀어서 실린더의 작동을 확인해

주십시오.

When the cylinder becomes inopera-

tive, operate the machine with the

following procedures for normal

operation as well as test run.

1. Stop the spindle if it is rotating.

2. Turn the pressure adjustment

handle of reducing valve on the

hydraulic unit, and raise the pre-set

chuck pressure by approx.

0.5Mpa. Then repeat changeover

of the cylinder operation

changeover switch to confirm

cylinder motion.

3. If the cylinder remains inoperative,

gradually increase the pre-set

chuck pressure (by approx.

0.5Mpa each) and repeat the same

procedures as described in above

(2) for confirmation of cylinder

motion. At this time, increase the

pressure to 30% of maximum

chuck pressure. When cylinder

operational, bring back the pre-set

chuck pressure to normal levels.

4. When unable to operate the cylinder

despite following the directions

above,bring the chuck pressure

down to normal level. Cool down

the cylinder until the surface

becomes room temperature.

Repeat steps (2) and (3)

Note) The cylinder can be cooled

faster by blowing air on the

cylinder with an air gun or

equivalent.

5. When cylinder does not operate

even after it is cooled, loosen the

draw-nut of the chuck for

confirmation of cylinder motion.

不仅在调试中,平时使用时也发生

出现上述气缸问题,请按照如下内

容调试。

1.若主轴正在旋转,请停止旋转。

2.旋转液压组件部位的夹头压力设

定(气缸设定压力)用减压阔的压力

调整把柄,将夹头设定压力约提高

0.5MPa, 并反转换气缸的动作切

换开关,检查气缸是否启动。

3.仍然不启动时, 请把夹头的设定

压力再提高一些(每次递增

0.5MPa), 如(2)一样反 操作,检

查气缸是否启动, 此时,提高压

力的上限应达到夹头最大使用压力

的30%, 气缸启动后,请把该压力

设定为原来夹头的设定压力。

4.把夹头的设定压力提高到最大程

度并按照(3)数次进行操作,气缸

仍不启动时,请把夹头的设定压力

调到原来 夹头的设定压力, 关闭

电源,使气缸表面温度冷却,使温

度几乎与室温相同,然后反进行上

述(2)、(3)项的 操作,检查气缸

是否启动。

注) 若使用空调机等向气缸吹冷

气, 可更快地冷却气缸。

5.气缸冷却以后若仍不启动,请松

开夹头侧的draw nut 然后检查气

缸是否动作。

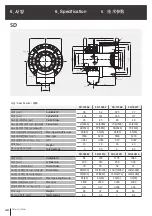

Summary of Contents for SD

Page 2: ......

Page 31: ...31 Instruction Manual n o t e...

Page 35: ...35 Instruction Manual n o t e...

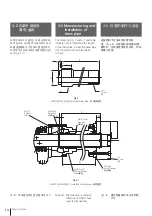

Page 38: ...21 26 19 20 23 25 18 17 22 16 15 24 38 Rotary Cylinder Fig 14...

Page 45: ......

Page 46: ......

Page 47: ......