English

Installation and operating instructions Ixens, Ixens Bloc

119

• The fan wheel has to be pressed on as far as possible when it is

installed. Only press here in the area of the hub.

11

Faults, causes and remedies

Have faults remedied by qualified personnel only! Observe the

safety instructions in chapter 10 “Maintenance” on page 112.

• If the malfunction cannot be rectified, consult a specialist techni-

cian or the nearest customer service centre or representative

office.

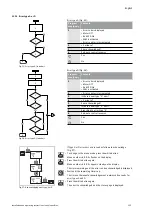

Fault indications

For faults, their causes and remedies, see the “Fault/warning mes-

sage” flow diagram in chapter 11.3 “Acknowledge fault” on page 122

and the following tables. The first column of the table lists the code

numbers displayed in the event of a fault.

NOTE:

If the cause of the fault no longer exists, some faults resolve them-

selves automatically.

Legend

The following types of errors can occur with differing priorities

(1 = lowest priority; 6 = highest priority):

11.1

Mechanical faults

Error type Description

Priority

A

A fault exists; the pump stops immediately.

The fault must be acknowledged at the pump.

6

B

A fault exists; the pump stops immediately.

The counter is increased and a timer counts

down. After the 6th fault, this becomes a def-

inite fault and has to be acknowledged at the

pump.

5

C

A fault exists; the pump stops immediately. If

the error exists for more than 5 min, the coun-

ter is increased. After the 6th fault, this

becomes a definite fault and has to be

acknowledged at the pump. Otherwise the

pump restarts automatically.

4

D

Like error type A, but error type A has a higher

priority than error type D.

3

E

Emergency operation: warning with emer-

gency operation speed and activated SSM

2

F

Warning – pump continues to turn

1

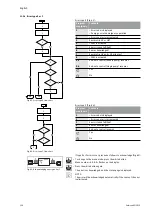

Fault

Cause

Remedy

Pump does not start or stops working Cable terminal loose

Check all cable connections

Fuses defective

Check fuses; replace faulty fuses

Pump runs at reduced output

Stop valve on the pressure side throt-

tled

Slowly open the stop valve

Air in the suction line

Repair leaks on flanges, vent the pump,

change the mechanical shaft seal in case

of visible leakage

Pump making noises

Cavitation due to insufficient supply

pressure

Increase supply pressure, observe mini-

mum pressure at the suction port, check

slide valve and filter on the suction side

and clean if need be

Motor has bearing damage

Have the pump checked by Salmson cus-

tomer service or a specialised service

centre and repaired if necessary

Summary of Contents for IXENS

Page 2: ......

Page 3: ......

Page 8: ...Fig 7 Ixens 13 20 22 21 15 16 17 18 19 14 13 12 11 10 9 8 7 4 3 2 1 6 5 20b 20a ...

Page 75: ...Français Notice de montage et de mise en service Ixens Ixens Bloc 67 ...

Page 137: ...English Installation and operating instructions Ixens Ixens Bloc 129 ...

Page 203: ...Italiano Istruzioni di montaggio uso e manutenzione Ixens Ixens Bloc 195 ...

Page 335: ......