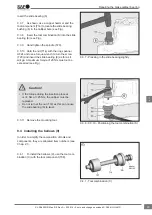

9.2.7 Caulk the bushing (7) against longitudinal

shift in the brake calliper. To this end, screw in the

hex screw (arrow B) of the embossed part (T16) as

far as it will go (see Fig.).

9.2.8 Screw back the hex screw (arrow B) of the

embossed part (T16) approx. 20 mm, loosen the

brass nut (T14) and turn the embossed part (T16)

approx. 60°. Repeat the caulking process. See

Fig. 9.2.7.

The bushing (7) is now caulked with the groove of

the brake calliper (arrow A).

9.2.9 Screw the spindle (T13) out of the em-

bossed part (T16) and remove the tool combination.

9.2.10 Check the seating of the bushing (7) for

burr formation and remove any burrs if necessary.

Smear the bushing (7) with white grease (supplied

in the repair kit).

9.3 Replacing the slide bearing (6) on

the short bearing side

In order to simplify the composition of tools and

components, they are allocated item numbers (see

Chap. 2.1).

9.3.1 To replace the slide bearing (6), use the tool

combination (5) (see Fig.).

Pulling out the slide bearing (6)

9.3.2 Remove the guide bushing (4)

9.3.3 Clean the bearing in the pad shaft area.

9.3.4 Position the tool combination (S) as shown

(see Fig.).

9.3.5 Hand tighten the nut (T14).

9.3.6 Hold the nut (T14) with the ring spanner

AF24 and use a suitable tool (e.g. ratchet wrench

AF24) to turn the screws on T20 and pull out the

slide bearing (6) (see Fig.).

9.2.7 - 9.2.8 - Caulking the bushing against

longitudinal shift

9.3.1 - Tool combinations (S)

9.3.4 - 9.3.6 - Pulling out the slide bearing

Repairing the brake calliper bearing

42

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND