The inner bellows (9) must be compressed

(see Fig.) as otherwise the movement of the

brake calliper will be restricted.

Caution!

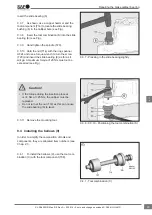

8.2.12 Using your hand, press the mandrel of

the press-in tool (H) as far as it will go. Then use

a hammer to drive it in as far as it will go (see

Fig. 8.2.12).

Note: After fitting the new cover (10), a 2 mm

protrusion of the cover (10) with respect to the flat

surface must be ensured (see Fig.).

Cover (68), short bearing side

The seating surface of the cover (68) in the calliper

bore must be free of grease!

8.2.13 Clean the new cover (68) thoroughly. Clean

the inside area of the press-in tool (M) and place

the cover inside (see Fig.).

8.2.14

Ensure that the flat surface and chamfer

of the calliper bore are not damaged - see arrow.

Position the press-in tool (M) with cover (68) on the

flat surface of the calliper bore (see Fig.).

Note: Do not tilt the tool!

The inner bellows (9) must compressed as

otherwise the movement of the brake calliper will

be restricted.

Caution!

8.2.12 - Driving the press-in tool (H) with a hammer

as far as it will go

8.2.13 - Placing the cover in the press-in tool (M)

8.2.14 - Positioning the press-in tool (M) with cover

on the flat surface of the calliper bore

Removing and installing the brake calliper

38

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND