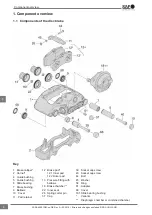

5.2.6.7 Measure the distance between the pad

backs and the pressure fitting (13).

Due to possible bridge tipping, this must be

measured with two gauges at the same time over

the entire surface of the pressure fitting and over

both pressure fittings (use 220 mm long feeler

gauges) (see Fig.).

If the clearance difference between the two

pressure fittings is >0.25 mm, the clearance of the

calliper guide must be checked for wear (see 5.3)!

In addition, the clearance at both pressure fittings

must be 0.6 - 1.2 mm.

If the clearance is too large, braking efficiency

may impaired. If the clearance is too small, the

brake may overheat and cause further damage.

Danger !

5.2.7 If the clearance is greater than 1.2 mm, the

adjustment function must be checked as follows:

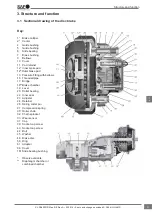

5.2.7.1 Rotate the adjuster with the adapter (61)

three clicks in an anti-clockwise direction (increas-

ing clearance).

5.2.7.2 Fit the ring spanner or socket to the adapter.

Actuate the brake 5 to 10 times (approx. 2 bar). In

the event of a functional adjustment, rotate the ring

spanner or socket cyclically in the direction of the

arrow (see Fig. and note below).

Note: As the cycle rate increases, the twisting angle or

movement of the ring spanner or socket decreases.

If the ring spanner or socket fails to rotate, does

so only on the first actuation or every actuation

backwards and forwards, the adjuster is faulty and

the brake calliper must be replaced.

5.2.6.7 - Measuring the distance between the pad

backs and pressure fitting

5.2.7.1 - Rotating the adjuster with the adapter

three clicks in an anti-clockwise direction

5.2.7.2 - Actuating the brake 5 to 10 times, the ring

spanner or socket must rotate cyclically

Ensure that the ring spanner can rotate freely

in a clockwise direction whilst carrying out the

following procedure.

Note !

Function and visual inspection

17

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND