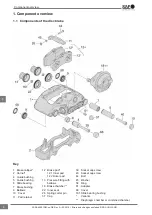

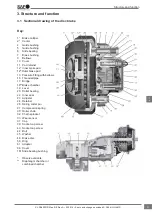

4. Inspection points

Although durable materials have been used,

the general condition of the components must

be checked on a regular basis. The following

information indicates the inspection points of the

disc brake, which if adhered to will help to ensure

long-term, problem-free use of the product.

Every 3 months

The wear state of the brake disc and brake pads

must be checked, irrespective of any indication in

the vehicle (see Chap. 5.1).

On each pad change

The adjustment function (see Chap. 5.2) and the

movement of the calliper over the entire movement

path (see Chap. 5.3) must be checked. In addition,

the pressure fitting bellows (13), cap (37), sealing

elements (9, 58) and calliper bearing in the slide

bearing (6) area must be checked for clearance and

damage (see Chap. 5.3.4).

Annually

The movement of the brake calliper within the

clearance (see Chap. 5.3.1) and the presence of

the cover (10), cap (37) and cover (68) must be

checked.

Note: These are minimum intervals. Depending on

use, more frequent component inspection may be

required.

Ensure to observe the information from the vehicle/

axle manufacturer with respect to service intervals

and legally stipulated inspections!

The brake discs must be inspected in accordance

with the information from the axle/vehicle

manufacturer.

To facilitate objective determination of the cause of

a complaint, all damaged parts must be returned in

the event of a complaint.

Inspection points

11

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND