5.1.4 Inspect the brake disc for run-in grooves

and cracks on every brake pad change and replace

if necessary.

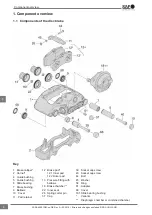

The image shows the possible states of the brake

disc surface.

A1 = Network-like formation of cracks is permissible

B1 = Cracks running towards the centre of the

hub to max. 1.5 mm (width and depth) and

max. 0.75 x a long are permissible

(a = friction ring width)

C1 = Unevenness of the disc surface to 1.5 mm is

permissible

D1 = Continuous cracks into the cooling channel

or to the inner or outer edge of the friction

ring are impermissible. The brake disc must

be replaced.

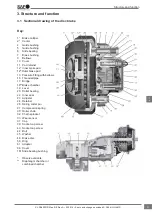

The image to the right shows examples of crack

and groove formation on a brake disc.

Notes: In surface states A1 to C1, the brake disc

can continue to be used until the maximum wear

dimension E = 37 mm is reached.

SAF-HOLLAND brake discs are maintenance-

free under normal conditions, i.e. polishing on pad

change is not required. D1 occurs only in isolated

cases and polishing of the brake discs is advisable

in order to increase the contact ratio of the brake

pad during the run-in process, e.g. in the event of

heavy scoring over the entire friction surface of the

brake disc. Minimum subsequent dimension after

turning down >39 mm.

In addition, the information from the vehicle

manufacturer with respect to turning down the brake

discs must be observed.

Ensure a consistent, all-over friction surface on the

friction ring. If necessary, replace the brake pads

and brake disc.

Brake disc polishing is impermissible.

Danger !

There is a risk of accident if these regulations are

not observed!

Worn brake pads and/or over-worn brake discs

will reduce or stop braking efficiency.

Danger !

5.1.4 - Brake disc tolerance and examples of crack

and groove formation on a brake disc

Function and visual inspection

14

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND